Alcoholysis of Algae Oil To Produce Biodiesel

Alcoholysis of Algae Oil To Produce Biodiesel

Volume 9, Issue 3, March – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24MAR1377

Alcoholysis of Algae Oil to Produce Biodiesel

Adeosun N O Olanrewaju A O

Chemistry Education Department, Chemistry Education Department

Federal College of Education (T) Asaba. Federal College of Education (T) Asaba.

Madaki S.D Ugboh E.

Computer Science Department, Computer Science Department,

Federal College of Education (T) Asaba. Federal College of Education (T) Asaba.

Abstract:- A technically and financially viable solution to I. INTRODUCTION

the numerous issues associated with fuel scarcity and high

cost is biodiesel. Algae biofuels represent a highly The need to find a substitute fuel has grown due to

promising alternative approach to energy generation. factors like environmental concerns, rising oil prices, and

Microalgae have been proposed as a viable alternative for reliance on foreign oil. The sustainable alternative energy

fuel production due to high oil content in their cells, source that garners the most attention in the present situation

making them suited for development as a material source is biodiesel, owing to its advantageous characteristics

for biodiesel manufacturing. This study used dry green including being easily biodegradable and ecologically

algae mass (Chlorophyceae) that was grounded into a beneficial. Oil obtained from algae is a renewable resource

smooth powder which was obtained from Delta state. A alternative to petroleum fuels, natural gas, and petroleum.

total of 100g of powder were measured. Also, biodiesel derived from oil crops is a possible renewable

and carbon neutral fuel (6, and 8). However, renewable oils

Algae oil extraction was done using lipid extraction. are not a strong rival to petroleum fuels because of their high

Additionally, acid esterification was the first step in the price and scarce availability.

characterization of biodiesel. Using a standard solution of

1.0M NaOH solution, the acid value of the reaction The use of vegetable oils gained popularity in the early

mixture was measured using a standard acid base titration 1980s due to concerns about the environment, energy security.

method. The results showed that the acid value was Since there is overproduction in agriculture, trans

0.280%, the iodine value was 128.592 mg/l, the specific esterification was found to be the most effective way to

gravity was 0.8103, the density was 0.8099 g/ml, the produce vegetable oils in place of petroleum fuels, as the latter

refractive index was read off as 1.41, the cloud points were became more expensive and less abundant. Investors and

-50C, the smokes were 2440C, and the flashes were likewise consumers started to find biodiesel becoming more attractive

288oC. (21, 15).

Using USA-based Buck Scientific M530, the analysis In the early 1990s, Martin Mittelbach was a member of a

method employed was FTIR, and FTIR spectra were co- group of pioneering researchers that worked on the creation of

added at 32 scans with a resolution of 4 cm-1. The spectra the biodiesel fuel industry in Europe and South Africa;

were collected at frequency areas of 4,000 – 600 cm-1. with the U.S. industry developed more slowly (17, 16). In

Transmitter values representing FTIR spectra were 1996, Pacific Biodiesel manufacturing production facility on

shown. Trans esterification is the technique used to turn the Hawaiian island of Miami to convert re-used cooking oil

algae oil into biodiesel. This was carried out in a round- into biodiesel, become one of the first biodiesel facilities in the

bottom flask with a magnetic stirrer and condenser using United States due to decreased pricing for petroleum fuel. (14,

catalyst that was supplied (three percent weight of the oil). 9).

Curves that are analytical were created. The

determination of the diglycerides and triglycerides was The Environmental Protection Agency (E.P.A.)

made possible by the analytical curves from diolein and estimated that algae is the only type of biofuel modelled to

triolein. After the product was dried at 800C in a vacuum date. Fatty acid methyl trans-esterification can reduce

evaporator, a clear and pure biodiesel was obtained. greenhouse gas emissions by more than 60 percent when

compared to petroleum diesel (19, 20). While using

microalgae as a fuel source is not a novel idea, the rising costs

of diesel and the effects of global warming have recently

propelled this solution to the top [2, 7].

IJISRT24MAR1377 www.ijisrt.com 1485

Volume 9, Issue 3, March – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24MAR1377

Chemistry classes in high school can be tedious and smooth powder by a small grinding machine for 1hr.30

challenging. However, if students perceive a means to alter the minutes which weighed 100g.

world, that tedious and difficult laboratory work in chemistry

may become an interesting and fun subject. A technically and Weighed sample was extracted using 500ml n-hexane in

financially viable solution to the numerous issues associated a soxhlet extractor (UNE-EN 734-1, 2006) for 5 hours. The

with expensive gasoline and shortage is biodiesel. Because extracted oil was placed in water bath at low temperature to

microalgae cells contain a lot of oil, they can be used as a evaporate the n-hexane from the extract. Extracted algae oil

material source for the manufacturing of biodiesel (13, 11). was weighed and stored in an air tight jar to avoid oxidation.

This prompted the researchers to investigate these procedures Lipid yield was calculated with this equation:

and turn algae mass into biodiesel. Students would gain

knowledge of the procedures used to produce biodiesel from Mass of Lipid

%𝐿𝑖𝑝𝑖𝑑 = ×100

Mass of sample

algae mass and be better equipped to propose solutions to the

high cost and limited availability of fuel in the future. Mass of Lipid (g)

%𝐿𝑖𝑝𝑖𝑑 = ×100

𝑀𝑎𝑠𝑠 𝑜𝑓 𝑚𝑖𝑐𝑟𝑜𝑎𝑙𝑔𝑒𝑎 (𝑔)

II. LITERATURE

An analysis was done on the extracted oil's fatty acid

Studies have demonstrated that switching to biodiesel profile using a Buck Scientific M530 USA FTIR. The spectra

from petroleum fuel lowers greenhouse gas emissions by more were obtained and modified using the Gram A1 software..

than 76%. Since civilization developed so quickly, there has Samples weighing around 1.0 g were added, along with 0.5 ml

been an increase in the usage of fossil fuels, which has of nujol, and thoroughly mixed before being put on the salt

decreased the reserves of these resources and severely harmed pellet.

the environment (14, 19). The development of new renewable

energy sources to displace fossil fuels is urgently needed in A. Determination of Fatty Acid (Acid Value)

order for international efforts to attain carbon neutrality (12,

19). Procedure

Distilled alcohol (25 ml), phenolphthalein (1 %), and 25

An innovative and environmentally friendly substitute ml of diethyl ether were combined, and carefully neutralized

for diesel fuel is biodiesel, which is made from renewable with 0.1 M NaOH. 1 - 10 g of oil or melted fat were dissolved

resources like vegetable or animal fat. Esters produced by in a mixed neutral solvent, and the mixture was titrated with

ethanol or methanol and long-chain saturated as well as aqueous 0.1M NaOH while being continuously shaken to

unsaturated fatty acids, including palmitic acid, stearic acid, produce a pink colour which persisted for a period of fifteen

oleic acid, and linoleic acid, constitute the vast majority of this seconds.

renewable resource (20, 15). As a result, researchers and

developers of biodiesel have drawn interest from academics B. Specific Gravity

all around the world.

Procedure:

As a result, the most viable substitute for fossil fuels is After a thorough cleaning with detergent, water, and

microalgae. Lipid found in microalgae, or the microalgae cell petroleum ether, the 50ml pycometer container was dried and

itself, can be used to generate liquid fuels like ethanol and weighed. Water was put into the bottle, weighed, and sealed.

liquid hydrocarbon fuels, as well as gaseous fuels like After the bottle was once more dried, the oil sample was

hydrogen and biogas (10, 8). Thus, the current stage of the added, and it was weighed.

development of microalgae biomass energy comprises the

generation of methane through anaerobic digestion (3, 7), the C. Refractive Index (RI)

synthesis of biodiesel from microalgae lipid through

transesterification (21, 4), and the production of hydrocarbons Procedure:

or substances resembling crude oil through gasification and Using a light compensator, the Abbe refract meter was

pyrolysis (9, 17). reset. The oil sample was seared on the lower prism of the

instrument and was closed. Light was passed by means of the

III. METHODOLOGY bungled mirror; the reflected light appeared in form of a dark

background. Fine adjustment was used to move the telescope

Dry green algae (Chlorophyceae) were used in this tubes until the black shadow appears central in the cross-wire

research which was obtained in Delta state. Every chemical indicator.

used for reagents and solvents was purchased from a

commercial supplier, and care has been taken to adhere to

analytical grade specifications. Dry algae were grinded into a

IJISRT24MAR1377 www.ijisrt.com 1486

Volume 9, Issue 3, March – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24MAR1377

D. Determination of Iodine Value Trans-esterification process was adopted to convert the

extracted algal oil into biodiesel. A catalyst weighed 3% of the

Procedure: oil was placed in a rotund bottomed flask having the

Oil was poured into a small beaker, small rod was condenser and magnetic stirrer. The reaction took 1 hr. to

inserted, then suitable quantity of the sample was weighed out complete at 60 ̊C. The proportion of oil to methanol was 10:1.

of the oil into a dry glass -stoppered bottle of about 250ml After the trans-esterification procedure, the combination of

capacity. The approximate weight in g of the oil was taken and methyl ester and glycerin \was left in a separating funnel for

was calculated using 20 to divide the highest expected iodine them to be separated for 16 hours.

value. 10ml of carbon tetrachloride was added to the oil or

melted fat and dissolved. Two layers were formed after the 16 hours, with

biodiesel at the top layer and glycerin as bottom of the funnel.

Also, 20ml of wijis’ solution was added, the stopper Glycerin layer was drained out of the funnel and the biodiesel

(previously moistened with potassium iodine solution) was was left. Hot water was spewed on the biodiesel to remove the

added and allowed to stand in the dark for 30 minutes. Also, soluble components which settled down at the bottom of the

15ml of potassium iodine solution (10%) and 100ml water was funnel. A vacuum evaporator at 80 0 C was used to dry the

added, mixed and titrated with 0.1M thiosulphate solution, impure biodiesel in order to achieve a very clear and pure

starch was used as indicator just before the end-point (titration biodiesel.

= aml). A blank was carried out at the same time which

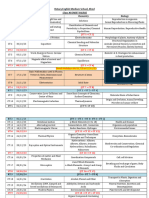

commenced with 10ml of carbon tetrachloride (titration = Table 3: Measurement and Determination of Glycerol

bml). (Free and Total), Triglycerides and Fatty Acid Methyl

Esther of Biodiesel According to ASTM D6584-08

IV. RESULTS Standard

Parameters Algae biodiesel

Table 1 Analysis of Algae Oil from Extraction. Ppm % components

Parameters Oil of Algae Triglyceride 0.7933 2.776

0.70 x 5.61 Alcohol 1.2082 4.228

Acid value % 2.199 = 1.786% Fatty Acid Methyl Ester 22.7882 79.737

2FFA = Acid Value Monoglyceride 0.9882 3.458

Free fatty acid % FFA = acid value/2 Glycerol 2.0994 7.346

= 1.786

2 = 0.893

Wt of flask +oil – wt of flask

Wt of equal volume of water

Specific gravity = 106.497 – 89.173

20

= 0.8662

(19.8 – 7.5) – 1.269

Iodine value 0.3

= 52.029

Melting point O C 6.0

Refractive index 1.42

Table 2: Characterization Compared with Global

Standard

Properties Units Chlorophyceae ASTM

D6584-08

Acid value KOH/g .560 .8 max

FFA % 0.280 --

Refractive index -- 1.41 --

Specific gravity

(28°C) g/ml .81 .88 Graph 1: Analytical Curves of Diolein and Triolein

Density g/ml 0.8099 - showing Both Diglycerides and Triglycerides

Iodine value mg/l 128.592 120 Determination.

IJISRT24MAR1377 www.ijisrt.com 1487

Volume 9, Issue 3, March – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24MAR1377

[2]. Cancela A, Maceiras R, Urrejola S, Sanchez A.

Microwave-Assisted Transesterification of Macroalgae.

Energies 2012, 5: 862-871.

[3]. Ehimen EA, Sun ZF, Carrington CG. Use of ultrasound

and co-solvents to improve the in-situ transesterification

of microalgae biomass. Procedia Environmental Sciences

2012; 15: 47-55.

[4]. Farooq Ahmad, Amin U. Khan and Abdullah Yasar

(2013) Transesterification of oil extracted from different

species of algae for biodiesel production June 2013

African Journal of Environmental Science and

Technology 7(6):358-364 DOI:10.5897/AJEST12.167

[5]. Hemwimon, S., Pavasant, P., and Shotipruk, A. (2007).

Microwave-assisted extraction of antioxidative

anthraquinones from roots of Morinda citrifolia. Sep.

Purif. Technol. 54, 44–50.

doi:10.1016/j.seppur.2006.08.014.

Graph 2 FTIR Curve To Assess Biodiesel Quality Using [6]. Jae-Yon L., Chan Y., So-Young J., Chi-Yong A., Hee-

ASTM D6584. Mock O., Comparison of several methods for effective

lipid extraction from microalgae. Bioresource

V. CONCLUSION Technology, 2010, 101, S75–

S7710.1016/j.biortech.2009.03.058

One hundred grams of Chlorophyceae algal biomass [7]. Jensen, G. S., Wu, X., Patterson, K. M., Barnes, J.,

were used to manufacture biodiesel in this research, the Carter, S. G., Scherwitz, L., et al. (2008). Improved Bligh

extracted algae oil was minimal and well-characterized. and Dyer extraction procedure. Lipid Technol. 20, 280–

Biodiesel was created by the tran sesterification process. After 281. doi:10.1002/lite.200800074.

then, left for 16 hours to separate from the glycerin. Every [8]. Jones, J., Manning, S., Montoya, M., Keller, K., and

process was carefully thought out and carried out. Poenie, M. (2012). Extraction of algal lipids and their

analysis by HPLC and mass spectrometry. J. Am. Oil

There is now a means for students to learn each stage of Chem. Soc. 89, 1371–1381. doi:10.1007/s00216-011-

the small-scale biodiesel production process. The students 5376-6.

gained an understanding of a variety of chemistry concepts, [9]. Koberg M, Cohen M, Ben-Amotz A, Gedanken A. Bio-

such as chemical processes, equations, equilibrium, and diesel production directly from the microalgae biomass

solubility. of Nannochloropsis by microwave and ultrasound

radiation. Bioresource Technology, 2011; 5 (102): 4265-

RECOMMENDATIONS 4269.

[10]. Krohn JB, McNeff VC, Yan B, Nowlan D. Production of

More investigation is needed into the creative methods algae-based biodiesel using the continuous catalytic

for gathering and separating microalgae biomass. The somatic Mcgyan process. Bioresource Technology 2011; 102: 94–

collection method, which is popular for extracting water from 100.

large volumes of microalga suspension, requires a significant [11]. Kumar M., Sundaram S., Gnansounou E., Christian

amount of time and energy. Since algal biomass bio refinery Larroche C., Thakur I.S., Carbon dioxide capture, storage

has only been implemented locally, more research is required and production of biofuel and Biomaterials by bacteria a

to create a new manufacturing process with large-scale, widely review. Bioresources, 2017, Technol.

applicable chemical applications that will benefit everyone. [12]. Maceiras R, Rodrı ´guez M, Cancela A, Urréjola S,

Sánchez A. Macroalgae: Raw material for biodiesel

REFERENCES production. Applied Energy 2011; 88: 3318–3323.

[13]. Özçimen D, Yücel S. Novel Methods in Biodiesel

[1]. Ali, F. Reinert L., Jean-Marc L, Duclaux L., Fabrice M., Production, In: Marco Aurélio dos Santos Bernardes

Shaukat S., Syed S.S. Effect of sonication conditions: (Ed.) Biofuel's Engineering Process Technology. InTech;

solvent, time, temperature and reactor type on the 2011. P353-384.

preparation of micron sized vermiculite particles, [14]. Patil P, Deng S, Isaac Rhodes J, Lammers PJ. Conversion

https://hal-insu.archives- of waste cooking oil to biodiesel using ferric sulfate and

ouvertes.fr/insu00876251; Submitted on 24 Oct 2013 supercritical methanol processes. Fuel 2009; 89 (2): 360-

364.

IJISRT24MAR1377 www.ijisrt.com 1488

Volume 9, Issue 3, March – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24MAR1377

[15]. Patil PD, Gude VG, Mannarswamy A, Cooke P, Munson-

McGee S, Nirmalakhandan N, Lammers P, Deng S.

Optimization of microwave-assisted transesterification of

dry algal biomass using response surface methodology.

Bioresource Technology 2011;102: 1399-1405.

[16]. Zada, S., Lu, H., Khan, S., Iqbal, A., Ahmad, A., Ahmad,

A., et al. (2021) Biosorption of iron ions through

microalgae from wastewater and soil: optimization and

comparative study. Chemosphere 265:129172. doi:

10.1016/j.chemosphere.2020.129172 CrossRef Full

Text | Google Scholar

[17]. Zeng, J., Wang, Z., and Chen, G. (2021). Biological

characteristics of energy conversion in carbon fixation by

microalgae. Renew. Sustain. Energy Rev. 152:111661.

doi:10.1016/j.rser.2021.111661

[18]. Sanghamitra, S., Deshmukh, S., and Narayan, K. P.

(2020). Effects of alternate nutrient medium on

microalgae biomass and lipid production as a bioenergy

source for fuel production. Mater. Today Proc. 28, 659–

664. doi: 10.1016/j.matpr.2019.12.238

[19]. Su, G., Ong, H. C., Gan, Y. Y., Chen, W., Chong, C. T.,

and Ok, Y. S. (2022). Co-pyrolysis of microalgae and

other biomass wastes for the production of high-quality

bio-oil: progress and prospective. Bioresour.

Technol. 344:126096. doi:

10.1016/j.biortech.2021.126096

[20]. Vignesh, P., Pradeep Kumar, A. R., Ganesh, N. S.,

Jayaseelan, V., and Sudhakar, K. (2021). Biodiesel and

green diesel generation: an overview. Oil Gas Sci.

Technol. 76:6. doi: 10.2516/ogst/2020088