Professional Documents

Culture Documents

Assessment On Post-Harvest Losses of Mango (Mangifera Indica L) and Allied Fungal Pathogens in Gambella Town Market, Southwest Ethiopia

Assessment On Post-Harvest Losses of Mango (Mangifera Indica L) and Allied Fungal Pathogens in Gambella Town Market, Southwest Ethiopia

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessment On Post-Harvest Losses of Mango (Mangifera Indica L) and Allied Fungal Pathogens in Gambella Town Market, Southwest Ethiopia

Assessment On Post-Harvest Losses of Mango (Mangifera Indica L) and Allied Fungal Pathogens in Gambella Town Market, Southwest Ethiopia

Copyright:

Available Formats

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Assessment on Post-Harvest Losses of Mango

(Mangifera indica L) and Allied Fungal Pathogens

in Gambella Town Market, Southwest Ethiopia

Solomon Nigusu*and MihretuYonas*

*Gmbella UniversityCollege of Agriculture and Natural

Resource Department of Plant Science and Horticulture, Gambella, Ethiopia, P.O.Box 126

Abstract:- The matter of post-harvest losses is extremely 400 AD (Yadav and Singh, 2017). It is the second among

important in the efforts to fightfamine, increaserevenue fruit crops in Ethiopia in its production coverage and

generations and recover food security in the world's economicstanding next to banana in Ethiopia. The largest

poorest countries. The greatestsignificantissues causing mango producing areas in Ethiopia are Harari region, west

countless economical loss of mango fruits are postharvest and east Oromia, Southern Nations, Nationalities, and

fungal diseases caused by absence of proper People’s Region (SNNPR), BenishangulGumuz Region,

management along postharvest chains. This study was Gambella Region and Amhara region which are valued to be

carried out to assess mango fruits postharvest loss, producing 35% of the majority of fruits produced about the

managementdoes and recognize the main allied agents of country (Akrong 2020; Fleming, 2020; Hagoset al., 2020).

postharvest fungal pathogens in Gambella town market. Western Ethiopia, especially the two zones (East and West)

Assessment was carried out by means of purposive of Wollega, of Oromia regional state, which is located in the

sampling to select the study part, followed by simple upper Blue Nile valley, is suitable for the production of

chance sampling to gather data through observation and mangoes (Temesgen, 2014). Mangoes are full-grown by the

interview. Fungi isolation was done at laboratory by mainstream of farmers living in aboutGambella town near

culturing on potato dextrose agar media under Baro bank River and farmers in the region were depend on

controlled growth conditions. The studyoutcomeshowed on old and largeincontrollable mango plants found in nature.

that losses of mango fruits due to spoilage and physical

damage were common problems for all fruit sellers. Mango fruits are extremely healthful, simplyedible and

Post-harvest loss of mango fruit was occurred in wide consumption is due to its sensory features, and mainly

different quantity along value chain actors. The most its good-looking texture and essencetype mango fruit

post-harvest loss of mango fruits occurred at market popular by the clients. Mango fruit has a high nutritive value

stage 23.33% and followed by harvesting stage 20%. and health welfares due to significant components such as

Market handling does such as lack of hygiene, phytochemicals. It is rich source of vitamins C, minerals, in

temperature management;inadequate packaging and dietary fiber, provitamin A, carotenoids and varied

transportation problems were recognised among the polyphenols (Esguerraet al., 2018). According to

mutual causes for mango fruit losses. The maximum Maldonado-Celiset al (2019) studies,mango fruit

mango fruit injury 40% was noted in sample taken from components can be assembled into macronutrients

retailers’ and the allied disease incidence 32% and (carbohydrates, proteins, amino acids, lipids, fatty, and

severity were 16% in the study part. Morphological organic acids), micronutrients (vitamins and minerals), and

documentation of pure culture indicated that most fungi phytochemicals (phenolic, polyphenol, pigments, and

associated with mango fruits loss was Colletotrichumspp volatile constituents). The nutritional, non-nutritional, and

40.51% among six genera of fungi isolated from mango water contents of mango fruit differreliant of the cultivar

fruits in Gambella town market. In general post- and numerous pre harvest and post-harvestissues (Corrales-

harvestlosses of mango fruits in the study part were Bernal et al., 2014).

accelerated by different factors. Furthermore, the

pathogenic of isolated fungi need to study to state their Even though mango fruits are extremelyessential as

effect on post-harvest loss of mango fruits including to nutritious and economically significant fruits, they knew by

controlling methods. different production limitations. According to some studies,

erratic rainfall, pest problems, improper agronomy practices,

Keywords:- Incidence and severity, post-harvest fungal lack of improved varieties, post-harvest losses and problem

pathogen, mango fruit handling, Value chain actors. of infrastructure were bottleneck of mango production in

Ethiopia (Honja, 2014; Siddiqet al., 2017). Mango is

I. INTRODUCTION anextremely perishable fruit, has a short shelf life and

vulnerable to environmental stress especially high

The mango (MangiferaindicaL.) is origin to India temperature. The perishable nature of harvest, lower

(Yadav and Singh, 2017) and most important fruit technology, and absence of awareness among makers as

commerciallycultured in tropical and subtropical areas of the well as market performerscaused in poor management of the

world (Mitra, 1997; Esguerraet al., 2018). Gradually, the mango fruits (Aberaet al., 2020). Substantialamounts of

mango moved from its centre of origin from Asia to the mangoes are lost each year during collecting, transport and

Middle East, East Africa and South America startabout 300- marketing (Hassan, 2010; Alamet al., 2019). Due to its

IJISRT23NOV2283 www.ijisrt.com 2639

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

perishable nature mango fruits necessitysupreme care plant pathology laboratory. Jimma University is located in

throughcollecting, cooling, storing, transporting, grading the city of Jimma Zone, located around 352 kilometres

and storing (Kayieret al., 2019).Fungal pathogens are southwest of Addis Ababa in Oromia region, Ethiopia.

frequently encountered on rotting mango fruits and were the Mango fruits post-harvest loss valuation and experiments

main agents of fruit rot after harvest and responsible for were done from March, 2021 to January, 2022.

postharvest diseases studied early by Sangchote (1989),

Rawal (1998) and Johnson (2008). The matter of post- B. Sampling and Data Collections Methods

harvest losses is extremelysignificant in the efforts to fight Pertinent data were collected using altered

hunger, increaseincome and progress food security in the questionnaires accepted from La Gra (1990) with semi

world's humblest countries like Ethiopia. A lot of structured interviews, formal questionnaires, direct

researcherstraced the decrease of post-harvest losses is observations and retrospective method (organizational

stated as akeysubjectconstituent of ensuring diagrams). The post-harvestmanagementlinkedstudies were

upcomingworldwide food sanctuary (Aulakhet al., 2013; ready; pre tested with sample defendants, rechecked for its

Garikai, 2014; Belik, 2018). precision for clear sympathetic and replying, and spread to

the respective selected representative respondents in

Moreover, bestinvestigationdirected on postharvest Gambella town market. The data were collected both from

losses of mango attentive on determinants Market Supply survey (Primary and secondary data) and laboratory

(Wake et al., 2013; Husen and Yimer, 20014; Kabeta and experiments. Yamane (1967) sampling formula with a 90

Alemu, 2019; Hagoset al., 2020). Recently, Tarekegn and percent confidence level and population proportional to size

Kelem (2022) studied about postharvest loss of mango along (PPS) to each residence of market was applied to get

value chain in Gamo zone SNNPR. However, not at allwide representative households respondents. Where “n” is sample

study has been done to findpost-harvest loss of mango from size for this study were (98), “N” is total number of mango

farm entrance to the point of eating due to fruits sellers were (4228) and “e” is margin of error at 10

unsuitablecollecting, post-harvestmanagement, carriage, percent.

intermediaries’ misconducts, storage and other details in

Gambella region, Ethiopia. There is no more information n= N .

about mango fruits handling practice in Gambella town 1+N (e) 2

market and causing agents of mango fruits loss. Therefore, it

suitspredictable to find the procedures and networks where Lastly, focus group discussions (FGDs) were led with

important losses and at what degree occur. A better importantgoal groups to get observations of different

understanding mango fruits handling practices could lead to stakeholders along with the product chain system and to

developing technology and does to decreasepost-harvest cross check the reliability of the information was gained.

losses of mango. However, little is understood about the Accordingly, the group discussions of producers were

effectallied fungal deterioration of the mango fruits. separated into two subgroups (men and women) for the

Additional, not at allwide study has been carried out so FGD. Extra and essentialdata was also gotten from key

distant to trace fungi allied with mango fruit spoilage informants, like development agents, agricultural officers,

causing losses and fungal deterioration. Hence, there is a and research professionals by connecting two FGDs with 7

vigorousessential to appreciate the impact of fungi spoilage members. The mango fruits postharvest management

during mango fruit marketing on the postharvest losses due doeswere also detected and noted. Mango fruits were bought

to fungal pathogens. Therefore, this study expected to from Gambella market traders (whole seller, retailer, farmer

evaluatedifferent postharvest doesaffecting postharvest and open market) and used for laboratory experiments to

losses and identified fungal pathogens accountable for the find the fungi allied mango fruit losing in the study area.

main postharvest deterioration of mango fruits in Gambella C. Data collected

town market.

Mango fruits harvesting tools

II. MATERIALS THEN METHODS To collect data regarding tools of mango fruits

A. Explanation of the Study Areas harvesting, the farmers were assessed and interviewed.

The postharvest loss valuation was carried out in During this data collected, about labour, harvesting tools,

Gambella town market, Gambella regional state of Ethiopia. harvesting method and time of harvesting was discussed and

Gambella region is one of eleven regional states of Ethiopia interviewed in the study area. All activities of postharvest

found at the south western region of the country and organization such as pre-cooling, grading, packaging,

bounded by South Sudan to the west, KellemWollega Zone, storage, loading and carriage were interviewed and stated.

Ilu Ababor Zone and Sheka Zone.Gambella is a name for Mango fruit post-harvest loss along value chain

both the regional state and the capital city of the region, Information were collected on mango fruits losses

which is located about 753 kilometres southwest of the happened in the harvesting, pre-cooling, field storage,

capital city of the country Addis Ababa perched at an sorting and grading, packaging, loading/unloading,

elevation of 526 meters above sea level. Gambella town transportation and marketing stages. Amount of producing

market is located in Gambella regional state capital city /buying/ and losing of mango fruits were interviewed in the

where fruits, vegetables, cereals and other products were study area.

sold. The laboratory investigation was directed at Jimma

University College of Agriculture and Veterinary Medicine,

IJISRT23NOV2283 www.ijisrt.com 2640

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Mango fruits handling practices in the Gambella town apparently healthy looking were sampled purposively

market centred on the capacity sell from the farmers selling fruits in

Information concentrating on issues linked to loss and farmers (n= 25), open market (n = 25), wholesalers (n =25),

their causes, farmer's exercise of management the mango and retailers (n = 25) with three replications. All the mango

fruits from production pending they take it to their buyer; fruits were transported to the laboratory and kept at room

their contact with the respective actors and government and temperature for additionalstudy of fruit injury and quiescent

physical flows of produce were collected. Moreover, (latent) contagion of the pathogens. The contagion of fungal

through data collection, temperature of the marketing part pathogens were documented using different approaches such

was noted three times in a day (morning, afternoon, and as looking at the appearance of rotten fruit, including the

evening) for successive 5 days, and the temperature of one color sign of the pathogen spore, and site of

day was averaged. contagionplaces. Following the documentation of infections,

disease incidence was calculated as number of infected

Fruit damage, disease incidence and severity valuation fruits display any single symptom out of entire number of

To measure percentage of mango fruits injury and test mango fruits sampled.

for fungal pathogen infection, representative samples (a total

of 100 mango fruits) composed of both damaged and

Percent of disease incidence= Number of infected fruits x100

Total number of fruit samples

Percentages of mango fruit damage were assessed and calculated using the following equation.

Percentage of mango fruits damage= Number of damaged mango fruits x 100

Total number of mango fruit samples

The disease harshness study was undertaken by >5%–25%, >25%–50%, >50%–75%, and >75% scored 2, 3,

detecting the fungal symptom record of disease levels 4, 5, and 6, respectively (Duamkhanmanee, 2008). The

according to the diseased surface part on the fruits. It was percent severity index of fungal impurity was then measured

measured on a 1–6 scale in which no diseased surface part from the numerical grades of the entire samples using the

scored 1, whereas the diseased surface parts of >0%–5%, next formula.

Percent severity index = Sum of numerical ratings x 100

Total number of mango fruit examined x maximum grade

Media preparation and growth conditions for fungi Isolation and documentation of fungal pathogens allied

culture with mango fruit

The media was prepared from PDA for fungi growth The samples collected from unalike mango sellers were

according to media fungi media preparation methods. Potato first eroded in blow water and then the fruits that

dextrose agar is the common media for any fungi growth in showedindications of fungal contagion were designated for

the laboratory under controlled growth conditions. PDA 39 fungal separation. The tissues were cut from lively lesions

gram was mixed in 1L of sterilized water. The mixed PDA and symptom showed surface of the mango fruits was used.

was stirred by magnet stirrer to mix well under hot The exterior of mango fruits tissues were sterilized by

condition. The well stirred and mixed media of PDA was soaking in freshly readyNaOCl (25 v/v) for 5 min. After

sterilized at 120 OC temperature and 105Kpa pressure for 15 three sequential washings in sterile purified water, mango

minute in autoclave. The sterilized media was poured in fruit tissues were engaged (four pieces per plate) on Potato

Petri dish under laminar air flow cabinet and left for 30 Dextrose Agar (PDA) and nursed at 25°C in the incubator

minute to media solidify and cool. The solidified and cooled for 3-7 days. The colonies emerged from each plated fruit

media were used for the experiments. The inoculated media tissues were cleaned and sub-cultured on the PDA media

were placed in growth chamber at 25 OC temperatures with after 6 days. The plates were nursed at 25°C under

good moisture. These media were replaced randomly in the comparablesituations, and the arrangements were

growth chamber with completely randomized design. The detectedpending the organisms convertedcompletely grown.

experiment done two times to get proper results and Single spore cultures of the fungus was then organized on

reducing error in the study. All growth conditions PDA slants in test tubes, and the empathy and description of

recommend for fungi growth were controlled and well noted the fungal separates were carried out centred on cultural and

in the laboratory. Similar and the some condition were morphological structures labelled in Marasaset al., (2001).

maintained for each experiment and all activities were The structure and morphological description was done by

equally applied for the study. preparing fungi fully grew on slide for identify under

microscope. The prepared slide where place under

microscope and morphology of fungi were considered with

three times pre Petri dish.

IJISRT23NOV2283 www.ijisrt.com 2641

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

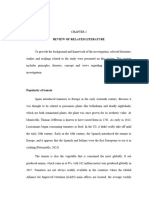

A B

C D

E F

Fig. 1: Photo captured during data collection (A) Transporting mango fruits by cart, (B) Mango fruits transporting by human

shoulder, (C) Packaging materials at market, (D) mango fruits in the Gambella town market captured by /CdeAyom, 2020/, (C)

temperature management and (F) Mango fruits not sort and graded.

D. Data Analysis III. RESULTS AND DISCUSSIONS

The freshinformation from the survey questionnaire

wasnoted, ordered and investigated using SPSS (version A. Socio-Demographic Characteristics of the Study Area

16.0) and Microsoft Excel 2007. Appropriate mathematical Among 98 mango fruits sellers interviewed, their gender,

calculations and inferences were made consequently. age, marital status, and educational ranks were specified

Expressive statistical examination (means, standard (Table 1). As result traced in Table 1, in gender group, 35

deviation, percentage and Chi-square) were used in (64.29 %) of respondents were females and rest of them

describing socio demographic, post- were males and showed that the females were tangled much

harvestmanagementperforms and alliedpost-harvest loss of in mango fruits sale. Among the age clusters, the maximum

mango fruits. Correlation analysis was used to search the of 30.61% members were between 35-45 years of age. The

relationship between post-harvest handling does and post- level of education differs among the gender and age groups,

harvest losses of mango fruits. An independent sample t-test 36.74% of them were illiterates, 63.26% of them were in

was also conducted to observe the significant effect of post- different levels (elementary to high school) education. More

harvest handling practices along with the mango fruits than 63.26% of literate respondents have attentiveness on

supply chain on its loss. Matrix grade was used to label the the effect of inadequatemanagementdoes on the quality of

relationship between socio demographic and mango fruits mango fruits. Alikethought was made by Olayemi,

post-harvest loss and to vital mango fruit marketing Adegbola, Bamishaiye, and Awagu (2012) who stated that

difficulties. peoples on secondary educational stages can simplyknow

the postharvest managementdoes more than peoples on

primary educational ranks. Babalola (2011) also stated that

education allowsunderstanding the result of

managementdoes on the postharvest loss of the produces

and mains to better managementensure than illiterate.

IJISRT23NOV2283 www.ijisrt.com 2642

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Table 1: Socio-demographic features of mango fruit sellers in Gambella town market

Variables in the study Frequency Percentage

Sex Male 35 35.71

Female 63 64.29

Age < 25 15 15.31

25 – 35 22 22.45

35 – 45 30 30.61

45 – 55 21 21.43

>55 10 10.20

Marital status Single 33 33.67

Married 60 61.23

Divorced 5 5.10

Education level Literate 36 36.74

Illiterate 62 63.26

Source: Own data computations (2022)

B. Post-Harvest Loss along the Mango Fruit Value Chain harvesting technology, awareness of societies about

and their Practices in the study area harvesting strategies, lack of harvesting materials,

Rendering to survey outcome mango fruits losses were mishandling during harvest and mismanagement were the

happened at collecting, pre-cooling, storing, sorting and driving force to mango fruits post-harvest loss in Gambella.

grading, packaging, loading/unloading, transportation, and At harvesting, separating the mango fruit from the stem

marketing and consumers stage with different percent of grounds the issue of resin and the sap, which has a low pH,

loss due to mismanagement and handling practices. can injury the fruit superficial. This injuryincreases the

Activities of the value chain actors and their contribution in addition of red and black spots and deteriorationgrowth on

mango fruits post-harvest losses were stated in the the peel, and concessions the fruit’s excellence. The

following. harvesters were not drained the sap from the fruit or

preserved to reduce the occurrence of sap burn. This was

Mango fruit harvesting practices and loss also one causative agent that enhancing post-harvest losing

Rendering to anemphasis group conversation with of mango fruits. The losing at harvesting stage 20% in this

mango producers, mango is collectedtypically once a year in study held second rank from value chain actors next to

the study part. This season for harvesting mango fruit starts market loss according to survey result (Figure 3). Therefore,

from February to May. In the study part, mango fruits were lack of harvesting technology, awareness of societies about

harvested regularly by family labor (78.5%), while the rest harvesting strategies, lack of harvesting materials,

were harvested by daily laborers (21.5%). Through the mishandling during harvest and mismanagement were the

harvesting time they were harvesting both matured and driving force to mango fruits post-harvest loss in Gambella.

immature mango by mixing. With respects to harvesting

implements, the defendantssettle that the better harvesting Pre-cooling and field storage of mango fruits and loss

apparatuses and mechanisms were not In this study area the farmers were not pre-cooling of

extensivelyexperienced by mango producers in Gambella. mango fruits to keep the excellence of fruits due to lack of

They were harvesting mango fruits in traditional ways and awareness of pre-cooling values. According to respondents

hand picking by ascending the mango tree. Old-styleways of in the study area the developed green fruits were not

collectinginstruments like trembling of the mango tree reserved at room temperature for around 4-10 days liable

branches, picking with a twig and cutting the fruit outlet upon the maturity for storage. The shelf life of mango fruits

were used in the study part. The farmers were harvesting the were not lengthy by pre-cooling, chemical treatments, low

mango fruits with stalk of the fruits in the study part. There temperature and in another mechanizes according to

were no technology provided in the study area to support respondent reflect. This study in line with Alkan and Kumar,

farmers to harvest in suitable manner and they were not (2018) studies stated thatover ripe mango fruits were more

trained how to harvesting the mango fruits in safety ways. vulnerable to post-harvest illness and mechanical injury,

while young fruit are prone to chilling pressurethrough cold

Post-harvest loss and excellencedecline during storage.

collecting and managementmethods were recognised by

20% of the respondents (Figure 3). As the respondents According to result in this study producers were

stated, they did not use the suggestedapparatus and directly took the mango fruits to the markets without any

resources for collecting and management due to absence of pre-cooling and field storage, due to this activities mango

admittance to bettercollecting technologies in the study part. fruits lost in the study around 6.66% and 3.33% respectively

These serious the risks of postharvest loss and quality (Figure 3). This losing was lower than another mango fruits

deterioration of mango fruits in the study area. This study value chain actors according result revealed in (Figure 3)

was not agree with the finding of Tarekegn and Kelem, when compared with each other. Pre-cooling really not

(2022) mango fruit lost was 73% at Gamo zone in SNNPR recommended for mango fruits being put through typical

in Ethiopia. This was due difference of harvesting methods postharvest handling and it was not showed more effect on

and techniques in the study area. Therefore, lack of post-harvest loss of mango fruits in the study part. However,

IJISRT23NOV2283 www.ijisrt.com 2643

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

pre-cooling was an effective and important strategy used for Mango fruits packaging practices

maintaining the quality of produce postharvest, to Wooden boxes, Plastic, sack, safa and basket were

implement pre-cooling into producing systems to prolong commonly used for packaging materials according to

the life and reservation the health of fresh mango fruits if respondent (Figure 1 C). Some of farmers were not used

adopted. packaging materials instead they were cutting the mango

fruits with stalk and hanging on the stem to take the markets

Sorting and grading mango fruit loss (Figure 1 B). About 31.25% of the defendants were used

Mango fruits producers in study area about 65% were Safa for wrapping mango fruits (Figure 2 C) and charted

sorting and grading the mango fruits based on the maturity, wooden box 25%, whereas the lingering of them were used

size, shape, freedom from disease, weight and color for basket, plastic, and sack (Figure 2). We detected that the

selling and transporting. According to the producers timber boxes they have been used were too large and too

responding most of producers were sorting the mango fruits uneven to deliverdefence and abundant of the fruits on the

before selling and estimated prices of each sorted mango lowest of the timber boxes were crumpled and

fruits and some of them were not sort and grading (Figure 1 classicallywaste before sale. However, the Safa was the best

C and F). For fresh marketing, the recognized methods of packaging materials in the study area and no more mango

classifying of mango fruits were physicalclassifying in the fruits damaged at the bottom due to over load. In this study

study part. There was no technology and machine developed area safawas most prominent packaging materials and best

for mango fruits grading and sorting in Gambella town tools people used in mango fruits holding and it held first

market. Farmers and producers were majorly sorting mango rank among all packaging materials stated (Figure 2) with

based on maturity and prices according respondent confirm 31.25 % according observation and respondent reflect

in the study area.Mango fruits loss was occurred about 10% (Figure 1 C).

according result traced in (Figure 3) and it was lower post-

harvest loss of mango fruits when compared with another Mango fruits post-harvest loss at packaging stage

value chain actors. Over ripening, mechanical injuring lower than another value chain actors according to

during harvest, immature, deformed shape, damaged due to respondents confirm about 3.33% were lost (Figure 3).

bird feeding and insect, cracking and price levels were some Related observation was made by Tarekegn and Kelem,

causing agents of mango fruit losing at this stage of value (2022) who stated a high mechanical damage to mango

chain actor according to respondent confirms. Mango fruits fruits crowded in timberbanger which could be due to

lost at this stage were lower than mango lost at marketing density and exteriorstaininginjuries. Mango fruits produced

levels according result stated (Figure 3). around Gambella town were directly transported to market

and packaging material encourage them to reducing loss

according respondent confirm. Focus group discussion and

key informative also encourage the idea of defendants in the

study part and stated that mango fruit packaging materials

help producers to reduce loss when compared with other

value chain actors (Figure 4).

Fig. 2: Percentage of respondent handling mango fruits using different packaging materials

Mango fruits transportation to the market and loss from the orchards, but they were not accepted in the study

The producers were transporting the mango fruits to the area in Gambella. Technology such as refrigerated vans/

markets using human labors, cart, Bajaj and other vehicles vesselsvaluable for extended distance carriage and help in

in the study area. Under active carriage situations shaking decreasing the postharvest losses was not adopted in this

affects in staining, deterioration and low price of mango study area. For carriagedrives, around 60% of defendants

fruits. The truck has been accepted as the used an old-style trolley, shoulder hanging and cart (Figure

greatestsuitablestyle of carriage due to its informaltactic 1 A and B), while nativegatherers and vendors use cars to

IJISRT23NOV2283 www.ijisrt.com 2644

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

carriage mango fruits. This study was not related with the means most sold mango fruits more than buyers according

finding of Tarekegn and Kelem, (2022) mango fruits to traders’ response in the study area.

transportation 87% at Gamo Zone in SNNPR by trolley and Unintendedperformersconnecting in mango value chain

cart. This may due to difference place of production area, were groups such as office of agriculture, trade office;

condition, strategies of transporting, management and research institutions, NGOs and financial institutions were

infrastructure in the study area. not more encourage them in required level. At market, there

was no vendible mango with small mechanical injury and

Due to transportation about 16.67% of mango fruits mango with slight decay in Gambella town market, this

were lost in this study area (Figure 3) and it was ranked enhancing mango fruits loss. This finding was related with

third among value chain actors in quantity of mango fruit the study of Alamet al., (2019), marketable mango losing

loss. The producers were transported mango fruits to the due to mechanical and decay injuries in Bangladesh. Market

markets in old-style ways this enhancing post-harvest loss of accessibility was a major bottleneck in post-harvest loss of

fruits. A study by Benyamet al, (2018) in Ethiopia stated mango fruits in Gambella town market.

that the use of old-style ways of carriage was increased post-

harvest loss. Means of their transportation such shoulder Mango fruits loading/unloading and loss

holding fruits, hand cart, safa and other materials were open Mango fruit loading/unloading in Gambella town market

and directly sunlight gain the fruits that increasing was scored and noted according to respondents reflects. In

metabolism activities of fruits. There were no technology this value chain actors the producers loading mango fruits

accepted for fruits management in the study area and there by throw means they were not replace the fruits on cart,

were trained men power encases of post-harvest Bajaj, truck and others means of transporting. This caused

management of fruits. According to respondent in study area mango fruits crack and breakage that enhancing fruit decay

mango fruits lost due to transportation services were high and loss. Due to this value chain actor about 6.67% mango

and focus group and key informative also confirm this fruits were lost in the study area. This losing was lower

result. Generally, lack of refrigerated transport, Lack of when compared with another value chain actors (Figure 3).

suitable transport system, poor infrastructure, loading and According focus group confirmed the producers have no

unloading doeswere enhancedpost-harvest loss of mango experience and knowledge of mango fruits

fruits in Gambella town market according the respondent loading/unloading; theoretically these were encouraging

direction. post-harvest loss of fruits. Therefore, uncaring handling of

free/packed mango fruits through loading and unloading

Mango fruits market accesses and loss producing loss.

The nativedealersbought mango fruits from producers on

anamount basis in the study part. More sources of mango Mango fruits loss at consumers

fruits happen from February to May in Gambella town According to result obtained from the respondents the

market. On the twitch and finish of the collectingperiod, the mango fruits lost at consumers levels were 10% among

fees of mango fruit were peak. At meddle of harvesting value chain actors (Figure 3).Physical damage was

mango fruits at high peak the prices fall and mango fruits pronounced in the harvesting system due to the lack of

accessibility found in the Gambella town market no more knowledge and training that causing mango fruits loss.

buyers found (Figure 1 D). A peak harvesting and Physiological losses, pathological losses, injure loss and

accessibility of mango fruits in the market it becomes cheap breakings of fruits were some reason accelerated the mango

and loss also occurred at the hands of traders. fruits loss at consumers’ stage. According to Adewoyinet

al, (2022) studies on fruits their results indicate fruits loss at

According to respondents confirm there were driving stage of consumers’ among value chain actors rage 5-10%.

force such as brokers, juice maker cafe and lack of industry This study also agrees with the finding of these scientists

of using mango fruits causing mango loss in the market. and the reason behind post-harvest loss were accelerated the

Under this value chain actor mongo fruits were lost 23.33% mango fruits damage in the study part. According to the

and held first rank among all value chain actors as results outcome stated in the Figure 3 the post-harvest losing of

indicated in (Figure 3). There were no infrastructure and mango fruits in the study part were lower than mango fruits

high peak producing mango fruits due to seasonality were lost at harvesting, marketing and transportation in Gambella

also another factor that affect the mango fruits loss. town markets.

Performerstangled in mango input source, making, selling

and worthcount for gettingrevenue as well as incomegetting

IJISRT23NOV2283 www.ijisrt.com 2645

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 3: Post harvest losses of mango fruits along value chain actors in Gambella town

Generally, the results of this study shown that the ambient situations. According the result shown in (Figure 4)

postharvest damage of mango fruits at diversephases of the traders were used different method to manage

source chain was varying to a least level with related to temperature in traditional ways such as cold water treatment,

managementdoes. The old-stylemanagementdoes of use umbrella shade, trees shade, shop and selling in open

postharvest organization mango fruits in Gambella were sunlight. Ten (10%) of the defendants sell mango fruits in

intuitive, labour intense, mishandling, mismanagement and umbrella shade structures (Figure 1 E and Figure 4) and

fewergainful. The highest loss occurred during Market 40% of them were used open sunlight envisioned for this

23.33% followed by Harvesting 20% and then transportation resolve (Figure 1 D and Figure 4).

16.67% in the study area. Even though the mango fruits loss

different among value chain actors, the most mango fruits The experimental temperatures of the marketing part

losing were scored and notedat market stage 23.33% (Figure was four to five fold advanced than the best postharvest

3). This outcome was similar with the result of Bantayehuet organization temperatures of mango fruits and hence, shelf-

al, (2017) post-harvest loss in tropical fruits. Therefore, life of the mango fruits would be hypotheticallylone one-

challenge to be occupied to distribute the better postharvest half. The high temperature improving the fungi

managementdoesmiddiverseshareholders at diversephases of development, water losing, spoilage, physiological and over

sourcehawser of mango fruits in Gambella town market. mature in short period of time. These activities were

encouraging post-harvest loss of mango fruits in the study

C. Mango Fruits Management Performs in Gambella Town part and there were not temperature managing technology

Market adopted. Traders in the study area well knew the effects of

Real remark and valuation outcomes stated an extensive high temperature, however they have not any option to

variety of mis management does that kindness fungal manage due to lack of required facilities according to

growths and outcomes in mango fruit losses. Postharvest respondent reflect. In all, depressing the temperature

mango fruits fungal growths and connectedharms could be decelerates fruit metabolism counting ripening, decreases

connected to the following mismanagementdoes. water loss, and decelerates the beginning and feast of

deterioration. Rendering to Silva (2008), every 10°C

Lack of temperature controlling increase in temperature, the respiration rate will rise at

The temperatures of the marketing part was noted for six minimum by two fold. High temperature induces rapid use

successive days and reached from 37 to 40°C during data of stored simple carbohydrate and produce energy through

collected. The noted temperature was ampleadvanced than respiration. Energy out upon postharvest respiration in fruit

suggested temperature for excellenceupkeep of the mango disturbs the sweetness, flavour, weight, turgor and loss of

fruits. Kader, (2015) recommended the best temperature of nourishment value of the fresh crop (Zainalabidinet al.,

13°C for mature green mango fruits and 10°C for somewhat 2019). This study also agrees with their ideas and findings

ripe and ripe mango fruits.This was typically 25–30 degrees means lack of temperature management and high

advanced than the suprememanagement temperatures temperature was a causing agent for tropical fruits loss.

suggested for the mango fruits. Most (45.82%) of the

defendants interviewed just left the fruits showing to

IJISRT23NOV2283 www.ijisrt.com 2646

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Fig. 4: Percent of temperature management methods during mango fruits selling in Gambella town market

Hygienerank of the market area Percentage of mango fruit injury

This one was saw that all the mango fruit sellingparts The proportion of mango fruit injury at the Gambella

were not useful only for fruits but diversesuppliesplus town market various among fruit managers (Table 2). The

cereals and vegetables were arrangedcomposed with the outcomedesignated that the extremeinjury 40% was detected

fruits. In 35% of the fruit selling shops, mango fruits were in sample engaged from retailers, and the smallest (8%) was

located with other fruits composed in the similarvessel noted from the sample engaged from growers selling their

which may principal to cross-contamination. More than mango fruits in the market (Table 2). Mango fruits injured at

26.40% of the defendantsmeasured that, the style of carriage open market in Gambella town market were 32% and it

was insanitary and mango fruits assorted with other fruits detained second rank among mango fruits sellers in the

with fewerupkeep for their injury in the study part. market.

Repliesaround the storingdated over which the mango fruits

sold securely were requested and the outcomeshown that Diverse details were designated as mainreasons for

42.50% of workshopskept only for 5 days in normal, while injury, and among these, carelessness in decent management

57.50% of mango fruit workshopskept the fruits only for 3 through collecting and on farm, absence of goodcarriage,

days in regular. This might be due to feast of fungal fewer care during loading and unloading, lack of

contagionas an outcome of absence of hygiene and pre- temperature management at market and old-style ways of

sorting to eliminaterotten mango fruits earliershowing to the packaging resources. More than 61.23% of the

market and in the workshops. defendantsexpressed that mango fruits sold in Gambella

market were lack temperature management and some

Altogether the defendantsdesignated that distance transportation fruits over loading and cracking

continuouslyobtainactuallydamaged and fit fruits in the fruits. These might induce physiological loss and

similarvessel from the producers. There is anoption of cross- mechanical injury on the fruits respectively and as an

contamination of vigorous fruits with fungal pathogens outcomebring fungal contagions. Moreover, there is no

(James, 2006). Throughout the period of remark, mango control technology for temperature, mishandling, injuring of

fruits were not separate from stack and not clean from fruits, turgor loss and packaging materials in the value chain

foreign materials this was some producing cross- actor. This may reasondescent of product trough increasing

contamination and fungi growth (Figure 1 F). Mishandling, physiological process of fruit and making favourable

lack of management, storing with other fruits or vegetables, situation for disease growth by waning the fruit cell wall and

adding unclean water for temperature running and lack of findings also related with Eduardo, (2012) studies.

sorting the injury mango fruits from healthy in Gambella Therefore, mango damaged occurred due to different factors

town market were produced mango fruits lack good occurred at different phase of value chain actors in the study

hygienist. part.

IJISRT23NOV2283 www.ijisrt.com 2647

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Incidence and severity of fungal pathogens good storage condition and lack of fungicide treatment were

The out of a hundred of disease occurrence and the majors factors accelerated mango fruits incidence and

strictnessvaried between mango fruit managers in Gambella fungi pathogens severity in the study area. Mechanical

town market (Table 2). The maximum incidence 32% was injury and natural opening parts of mango fruit were also

noted in sample booked from retailers followed by sample support fungi to enter in fruits and causing mango fruits

from open market 24%. In the similarway, the mean percent spoilage and decay. Generally, mismanagement of post-

of disease strictness was supreme at retailers’ and least in harvest caused the development of fungi pathogens and

sample booked from farmers (Table 2). The mean brings incidence and severity of disease that enhancing post-

percentage of disease occurrence and strictnessoutcomes harvest loss of mango fruits. Other study alsodesignatedthat

were in line with percentage of fruit injurynoted. The mechanical injurythroughmanagement at different phases

variance in terms of fruit injury, percent disease occurrence, along postharvest chain prompts the fruits for fungal

and severity among mango fruit managers could be due to pathogens (Hailuet al, 2012). Related result also shown in

storing and others issues.Traditional handling, careless Kuyu and Tola, (2018) study on assessment of postharvest

loading/unloading/, lack of temperature management, lack losses among banana fruits in Jimma town market.

Table 2: Percentage of infection incidence, injury and severity from different mango fruit handlers in Gambella town market

Mango fruit handlers Damage (%) Incidence (%) Severity (%)

Farmers 8.00 12.00 9.33

Whole seller 24.00 20.00 12.8

Retailers 40.00 32.00 16.00

Open market 32.00 24.00 10.67

D. Documentation and description of fungal pathogens spoilage and decay in Gambella town market. The cultural

allied with mango fruit and morphological soundings on the samples shown that

Mango fruits are extremely perishable fruits and Colletotrichumgloeosporioideswas the most frequently

actualdisposed to to fungal contagion. Anentire of 129 observed fungi allied with mango fruits 46.51% (Table 3) in

fungal separatesassembled in six (6) genera were study area. Onyeaniet al, (2012) and Ahmed and

recuperated from mango fruit samples composed from four Mohammed, (2014) studied fungi allied with mango fruits

fruit managers (growers, open market, traders and vendors) and this result was related with their findings. Fungi isolated

of Gambella town market. They were known on the origin from mango fruits decay and spoilage (Figure 5 A) was

of their cultural and morphological buildings such as shapes associated with mango fruits post-harvest lost in the study

and sizes of macroconidia and microconidia, colony and area. Fusariumspp30% andAspergillusspp25% was

color. According to the result shown (Table 3) Alternariaspp frequently occurred according to result stated in (Table 3).

9%, Aspergillusspp 25%, Colletotrichumspp 40.51%, Entylomaspp1.55% andPenicilliumspp2.33% was lest fungi

Entyloma spp1.55%, Fusariumspp 30% andPenicilliumspp species allied with mango fruit in the study area when

2.33% were the genus of fungi associated with mango fruits compared with another species depicted in (Table 3).

Table 3: Number of fungi allied and isolated from mango fruits decay and spoilage from Gambella town market

Fungi spp isolated Number of isolated Percent of isolated (%)

Alternaria alternate 6.00 4.65

Alternariatenuissima 3.00 2.33

Aspergillusflavus 2.00 1.55

Aspergillus fumigates 4.00 3.10

Aspergillusnidulans 7.00 5.43

Aspergillusnigur 12.00 9.30

Colletotrichumgloeosporioides 60.00 46.51

Entylomaspp 2.00 1.55

Fusariumdimerum 10.00 7.75

Fusariumlongipes 14.00 10.85

Fusariumverticillioides 6.00 4.65

Penicilliumspp 3.00 2.33

IJISRT23NOV2283 www.ijisrt.com 2648

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

A B

C D

Fig. 5: Photo captured during experiment done (A) sample used for fungi isolation and post-harvest spoilage, (B) Inoculated and

culture fungi on Petri dish, (C), pure cultured and (D) pure culture left for mature and spore forming for identification.

IV. SUMMARY AND CONCLUSIONS commodities counting cereals and vegetables were loaded

together with the fruits. These activities were the causing

Mango is in request in the worldwide market owing to cross contamination and brought mango fruits loss in the

its outstanding flavour, strikingscent, and taste, nourishing study part according to respondent confirms. The percentage

and ant-nutritional properties. Though, it is of mango fruit injury at the Gambella town market varied

extremelyperishable meanwhile it ripens simply after among fruit handlers.

harvest and it is vulnerable to postharvest losses.Doubt they

are unprotected to adverse ecological situations through The outcome designated that the extremeinjury 40%

management, the tissue will unstiffen and simply damage, was detected in sample booked from retailers. Disease

producing fast microbial decline. In the study part, strength had alikedrifts with percentage of mango fruit

excellence and care guarantee eglitches such as absence of injury with extrainjury, and contagions were noted in

temperature organization, consistency of excellence within retailers. The one hundredth of fruit injurywas as high as

vessels, hygienedifficulties in the marketplace, 40%, and the allied disease occurrence 32% and

carriagelinkedglitches, uncaringmanagementthrough loading sternness16% in retailers. Mongo fruits injury at different

and unloading were known as the foremostinfluences of stage value chain were caused mango fruits post-harvest

mango fruits loss. These factors werefavorite fungal disease. Bruising, breaking, injuring, damaging and spoilage

pathogen growth,reproduction and related mango fruit were support for fungi development and caused mango

losses.Mango fruits lost were happened along value chain fruits post-harvest loss in the study area. About 129 fungi

with different quantities in Gambella town market. The most allied with mango fruits spoilage and decay in Gambella

mango fruit lost was happened at market stage of mango town market was isolated. According to the result shown

fruits with 23.33% and this followed by mango harvesting (Table 3) Alternariaspp, Aspergillusspp, Colletotrichumspp,

stage with 20% lost. According to respondent in the study Entylomaspp, Fusariumspp, andPenicilliumsppwere the

area mongo fruits losing at market level was due to different genus of fungi related with mango fruits in the study area.

factors such as high pick of production, lack of good Mechanical damage due to mismanagement along stream

management, lack of temperature, mishandling and mango chains and hygienictricky in the market could be the

fruits injured were factors raised. Postharvest mango fruits likelyreasons for detected fungal pathogens. In directive to

fungal growths and allied losses could be connected to the decrease mechanical damage and relatedinfectiousdecline, a

mismanagementdoes during harvesting and marketing. In close combination of all participants along the value chain

the study area most of sellers used open sunlight marketing of mango fruits develops essential.

that was causing physiological loss. Some respondents

stated different methods of temperature management in old- Mango fruits managers with advanced levels of proper

style ways. It was experimental that all the mango fruit education had lesser post-harvest losses than those with

sellingparts were not usefullone for fruits but diverse minor education stages and demonstratingwell post-harvest

managementdoes by expertmanagerssince of their capacity

IJISRT23NOV2283 www.ijisrt.com 2649

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

to know and accept new technologies fast. In this study the (2003). Handling and preservation of fruits and

most mango fruits lost were counted at marketing 23.33% vegetables by combined methods for rural areas:

among value chain actors. Lack temperature management, Technical manual. FAO Agricultural Services

mishandling, lack of sanitation and cross contamination (Bulletin, 149.

were caused post-harvest losing of mango fruits in the [11]. Bantayehu, M., Alemayehu, M., Abera, M. and

markets. The result of this study showed 40% mango Solomon, B., (2017).Postharvest losses assessment of

fruitsdamage, incidence 32% and severity 16% were the tropical fruits in the market chain of North-Western

most scored result at mango fruits handlers. Among six Ethiopia. Food Science and Quality Management, 66.

fungi genera isolated from mango fruits decay and spoilage [12]. Fleming, M., (2020). An Analysis of Women-Led

most frequently happened fungi allied was Enterprises in the Mango Value Cahin in Emerging

Colletotrichumspp 40.51%. Therefore, mango fruit Economies: Case Study of Azuri Health Ltd. In Thika,

managersneed to be trained on the newestsuitable and Kenya.

inexpensive technologies beginning from farmers [13]. Garikai, Maremera, (2014). Assessment of Vegetable

packaging, conveying and progressive techniques and Postharvest Losses among Smallholder Farmers in

approaches of post-harvest management. Furthermore, Umbumbulu Area of Kwazulu-Natal Province, South

occupied on post-harvest managementdoes and Africa, PhD Diss. University of KwaZulu-Natal,

sellingschemeovercollaborationinside Unions, NGOs and Pietermaritzburg.

other governmental organizations is desired. [14]. Hagos, A., Dibaba, R., Bekele, A. and Alemu, D.,

(2020). Determinants of market participation among

REFERENCES mallholder mango producers in Assosa Zone of

BenishangulGumuz Region in Ethiopia. International

[1]. Abera, G., Ibrahim, A.M., Forsido, S.F. and Kuyu, Journal of Fruit Science, 20(3), pp.323-349.

C.G., (2020). Assessment on post-harvest lossesof [15]. Hailu, M., Workneh, T.S. and Belew, D., (2012).Effect

tomato (Lycopersiconesculentem Mill.) in selected of packaging materials on the quality of banana

districts of East Shewa Zone of Ethiopia using a cultivars. African Journal of Agricultural

commodity system analysis Research, 7(7), pp.1226-1237.

methodology. Heliyon, 6(4), p.e03749. [16]. Honja, T., (2014). Review of mango value chain in

[2]. Alkan, N. and Kumar, P., (2018). Postharvest storage Ethiopia. Journal of Biology, Agriculture and

management of mango fruits. AchievingSustainable Healthcare, 4(25), pp.230-240.

Cultivation of Mango; GalánSaúco, V., Lu, P., Eds, [17]. Hussen, S. and Yimer, Z., (2013).Assessment of

pp.377-402. production potentials and constraints of mango

[3]. Akrong, R., (2020). An Economic Assessment of the (Mangiferaindica) at Bati, Oromia zone,

Factors That Influence Smallholder Ethiopia. International Journal of Sciences: Basic and

[4]. Farmer Participation in Export Markets as a Case of Applied Research, 11(1), pp.1-9.

High Value Mango Markets inSouthern [18]. Johnson, G.I., (2008). Status of Mango Postharvest

Ghana (Doctoral dissertation, University of Nairobi). Disease Management R & D: options and solutions for

[5]. Alam, S.M.K., Rahman, M.A. and Reza, M.H., (2019). the Australian mango industry. HorticAus Final Rep

Postharvest loss assessment of mango at different proj MG08017, Hortic, 4.

stages of supply chain through traditional and [19]. James, J., (2006). Overview of microbial hazards in

improved handling practices. Adv Plants Agric fresh fruit and vegetables operations. Microbial hazard

Res, 9(3), pp.384-388. identification in fresh fruit and vegetables, pp.1-36.

[6]. Alkan, N. and Kumar, P., (2018). Postharvest storage [20]. Kader, A. and Mitcham, B., 2008. Optimum

management of mango fruit. Achieving Sustainable procedures for ripening mangoes. Fruit ripening and

Cultivation of Mango; GalánSaúco, V., Lu, P., Eds, ethylene management, 47, p.48.

pp.377-402. [21]. Kuyu, C.G. and Tola, Y.B., (2018). Assessment of

[7]. Alkan, N., Friedlander, G., Ment, D., Prusky, D. and banana fruit handling practices and

Fluhr, R., (2015). Simultaneous transcriptome analysis [22]. associated fungal pathogens in Jimma town market,

of C olletotrichumgloeosporioides and tomato fruit southwest Ethiopia. Food science

pathosystem reveals novel fungal pathogenicity and &nutrition, 6(3), pp.609-616.

fruit defense strategies. New Phytologist, 205(2), [23]. Mahajan, P.V., Caleb, O.J., Singh, Z., Watkins, C.B.

pp.801-815. and Geyer, M., (2014). Postharvest treatments of fresh

[8]. Aulakh, J., Regmi, A., Fulton, J., Alexander, C., produce. Philosophical Transactions of the Royal

(2013). Food losses: developing a consistent global Society A: Mathematical, Physicaland Engineering

estimation framework. In: Agricultural and Applied Sciences, 372(2017), p.20130309.

Economics Association Annual Meeting, August 4-6. [24]. Maldonado-Celis, M.E., Yahia, E.M., Bedoya, R.,

[9]. Ahmed, R.A.N. and Mohammed, S.A.S., (2014). Landázuri, P., Loango, N., Aguillón, J., Restrepo, B.

Isolation and classification of fungi associated with and Guerrero Ospina, J.C., (2019).Chemical

spoilage of post-harvest mango (Mangiferaindica L.) in composition of mango (Mangiferaindica L.) fruit

Saudi Arabia. African Journal of Microbiology Nutritional and phytochemical compounds. Frontiers

Research, 8(7), pp.685-688. in plant science, p.1073.

[10]. Barbosa, C.G., FERNÁNDEZ, J., Alzamora, S.M.,

Tapia, M.S., López, M.A. and Welti, C.S.J.,

IJISRT23NOV2283 www.ijisrt.com 2650

Volume 8, Issue 11, November 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[25]. Onyeani, C.A., Osunlaja, S.O., Owuru, O.O. and

Sosanya, O.S., (2012).Mango fruit anthracnose and the

effects on mango yield and market values in

Southwestern Nigeria. Asian Journal of Agricultural

Research, 6(4), pp.171-179.

[26]. Prusky, D., Alkan, N., Mengiste, T. and Fluhr, R.,

(2013).Quiescent and necrotrophic lifestyle choice

during postharvest disease development. Annual

Review of Phytopathology, 51, pp.155-176.

[27]. Rajmane, S.D. and Korekar, S.L., (2016). Isolation and

identification of fungi associated with spoilage of

mango fruit, India. International Journal of Scientific

Research, 5(8), pp.2277-8179.

[28]. Rajan, S., Mishra, P.K., Srivastav, V., Aditya, K.,

Sagar, P. and Tripathi, P.K., (2020). A study on the

visitor preference for different modules of the National

Mango Database. Journal of Applied

Horticulture, 22(2), pp.117-121.

[29]. Siddiq, M., Brecht, J.K. and Sidhu, J.S. eds.,

(2017). Handbook of mango fruit: production

postharvest science, processing technology and

nutrition. John Wiley & Sons.

[30]. Singh, S.P. and Singh, Z., 2012. Postharvest oxidative

behaviour of 1methylcyclopropene treated Japanese

plums (PrunussalicinaLindell) during storage under

controlled and modified atmospheres. Postharvest

biology and technology, 74, pp.26-35.

[31]. Sivakumar, D., Jiang, Y. and Yahia, E.M., 2011.

Maintaining mango (Mangiferaindica L.)Fruit quality

during the export chain. Food Research

International, 44(5), pp.1254-1263.

[32]. Sophia, O., Robert, G.M. and Ngwela, W.J., (2015).

Effect of Aloe vera gel coating on postharvest quality

and shelf life of mango (Mangiferaindica L.) fruits

Var. Ngowe. Journal of Horticulture and

Forestry, 7(1), pp.1-7.

[33]. Temesgen, F., (2014). White mango scale,

Aulacaspistubercularis, distribution and severity status

East and West Wolega zone, Western

Ethiopia. Science, Technology and Arts Research

Journal, 3(3), pp.1-10.

[34]. Tarekegn, K. and Kelem, F., (2022).Assessment of

Mango Post-Harvest Losses along Value Chain in the

Gamo Zone, Southern Ethiopia. International Journal

of Fruit Science, 22(1), pp.170-182.

[35]. TemesgenKabeta and JemberuAlemu.(2019).

“Determinants of Mango Market Supply and Outlet

Choice: The Case of Gambella and Itang Special

Districts of Gambella Regional State, Ethiopia". Acta

Scientific Agriculture 3.12 (2019): 32-39.

[36]. Zainalabidin, F.A., Sagrin, M.S., Azmi, W.N.W. and

Ghazali, A.S., (2019). Optimum postharvest handling-

effect of temperature on quality and shelf life of

tropical fruits and vegetables. Journal of

Tropical Resources and Sustainable Science

(JTRSS), 7(1), pp.23-30.

IJISRT23NOV2283 www.ijisrt.com 2651

You might also like

- Battlegroup Final Draft Pass 9-29-2021 Bookmarked CYANDocument295 pagesBattlegroup Final Draft Pass 9-29-2021 Bookmarked CYANbob bisbetico bislacco100% (2)

- A Guide to Good Agricultural Practices for Commercial Production of Ginger under Field Conditions in JamaicaFrom EverandA Guide to Good Agricultural Practices for Commercial Production of Ginger under Field Conditions in JamaicaRating: 5 out of 5 stars5/5 (1)

- Postharvest Loss Assessment of Banana at Jimma Town Market.Document8 pagesPostharvest Loss Assessment of Banana at Jimma Town Market.Premier PublishersNo ratings yet

- Agricultural and Natural ResourcesDocument9 pagesAgricultural and Natural ResourcesazhariNo ratings yet

- Postharvest Loss Vegetables-AL Acedo JRDocument12 pagesPostharvest Loss Vegetables-AL Acedo JRAntonio acedoNo ratings yet

- Morphological Characteristics of Colletotrichum Species Associated With Mango (Mangifera Indica L.) in Southwest EthiopiaDocument10 pagesMorphological Characteristics of Colletotrichum Species Associated With Mango (Mangifera Indica L.) in Southwest Ethiopiasahudebasish543No ratings yet

- An Analysis of Yam Production in NigeriaDocument8 pagesAn Analysis of Yam Production in NigeriaESTHER OGODONo ratings yet

- Corrected - 2020 1 11Document8 pagesCorrected - 2020 1 11ayuba abakaNo ratings yet

- Factors Affecting Pineapple Market Supply in Johor, MalaysiaDocument10 pagesFactors Affecting Pineapple Market Supply in Johor, MalaysiaawalNo ratings yet

- (Journal of Horticultural Research) Profitability and Constraints of Pineapple Production in Osun State NigeriaDocument6 pages(Journal of Horticultural Research) Profitability and Constraints of Pineapple Production in Osun State NigeriathanhvtpNo ratings yet

- Mdnor 2020Document17 pagesMdnor 2020LU'LU'IL MAKNUNINNo ratings yet

- Marketing AspectDocument13 pagesMarketing AspectTrisha Jamaica De LeonNo ratings yet

- 1 PBDocument8 pages1 PBZedo aynalemNo ratings yet

- Houngbo Et Al - 2019 - Stakeholders' Perception of Weaver Ant's EffectsDocument10 pagesHoungbo Et Al - 2019 - Stakeholders' Perception of Weaver Ant's EffectsAnato FlorenceNo ratings yet

- Resource Use Efficiency Among Sweet Potato Farmers in Ifedore Local Government Area of Ondo StateDocument7 pagesResource Use Efficiency Among Sweet Potato Farmers in Ifedore Local Government Area of Ondo StateMamta AgarwalNo ratings yet

- Mango Value Chain AnalysisDocument24 pagesMango Value Chain AnalysisBirukNo ratings yet

- Review of Postharvest Loss of Horticultural Crops in Ethiopia Its Causes and Mitigation StrategiesDocument4 pagesReview of Postharvest Loss of Horticultural Crops in Ethiopia Its Causes and Mitigation StrategiesZerihun ZenaNo ratings yet

- Baltazari 2019Document17 pagesBaltazari 2019hai leNo ratings yet

- Herbicides perception and utilization among cassava farmers in Delta State, NigeriaDocument12 pagesHerbicides perception and utilization among cassava farmers in Delta State, NigeriaOpenaccess Research paperNo ratings yet

- ABE321_0207Document4 pagesABE321_0207Jefrey M. ButilNo ratings yet

- 005 Icoia2014 Ia0015Document6 pages005 Icoia2014 Ia0015Nohj DohinogNo ratings yet

- Amevoin2021 Article FruitFlySurveillanceInTogoWest PDFDocument16 pagesAmevoin2021 Article FruitFlySurveillanceInTogoWest PDFBabugi Ernesto Antonio ObraNo ratings yet

- Chapter 2Document10 pagesChapter 2Daryl AlamanNo ratings yet

- 10.-A-REVIEW-ON-ANTHRACNOSE-OF-MANGO-CAUSED-BY-COLLETOTRICHUM-GLOEOSPORIOIDES 1111 ColleDocument10 pages10.-A-REVIEW-ON-ANTHRACNOSE-OF-MANGO-CAUSED-BY-COLLETOTRICHUM-GLOEOSPORIOIDES 1111 Collephamvanson1tNo ratings yet

- Review On MangoDocument11 pagesReview On MangoDaguale Melaku AyeleNo ratings yet

- The Benefits of Market Gardening in A Context of Food Insecurity in The Commune of Djirataoua in NigerDocument13 pagesThe Benefits of Market Gardening in A Context of Food Insecurity in The Commune of Djirataoua in NigerMamta AgarwalNo ratings yet

- A Study of Pathogenic Fungi Causing Post Harvest Losses of Pineapple Sold at Wudil and Yan Lemo Markets of Kano StateDocument6 pagesA Study of Pathogenic Fungi Causing Post Harvest Losses of Pineapple Sold at Wudil and Yan Lemo Markets of Kano StateShobujurRahmanNo ratings yet

- NURSERY PROTECTION TO ENHANCE AGRICULTURAL YIELD AND PROMOTE SUSTAINABILITY IN CHILLI FARMINDocument13 pagesNURSERY PROTECTION TO ENHANCE AGRICULTURAL YIELD AND PROMOTE SUSTAINABILITY IN CHILLI FARMINevyNo ratings yet

- Agriculture, Ecosystems and EnvironmentDocument9 pagesAgriculture, Ecosystems and EnvironmentNelson CuriñirNo ratings yet

- 2019 Mango Postharvest Losses Aug 2019Document6 pages2019 Mango Postharvest Losses Aug 2019Md AhiduzzamanNo ratings yet

- French Beans ConstraintsDocument4 pagesFrench Beans ConstraintsFelix King MensahNo ratings yet

- PineapplesDocument10 pagesPineapplescecille maningoNo ratings yet

- Assessment of Post-Harvest Handling Practices Knowledge and Losses of Fruits in Bagamoyo District of TanzaniaDocument9 pagesAssessment of Post-Harvest Handling Practices Knowledge and Losses of Fruits in Bagamoyo District of TanzaniaAlexander DeckerNo ratings yet

- (Bagal, Sheikh & Adsule, 1989) - (Food and Agriculture Organization (FAO), 2016) - (FAO, 2016)Document3 pages(Bagal, Sheikh & Adsule, 1989) - (Food and Agriculture Organization (FAO), 2016) - (FAO, 2016)လင္း ထိုက္100% (1)

- Postharvest Biology and Technology: E.O. Gogo, A.M. Opiyo, Ch. Ulrichs, S. Huyskens-KeilDocument9 pagesPostharvest Biology and Technology: E.O. Gogo, A.M. Opiyo, Ch. Ulrichs, S. Huyskens-KeilJoao Lecca RuízNo ratings yet

- A-Farmers' Preferences For The Design PFA KenyaDocument12 pagesA-Farmers' Preferences For The Design PFA Kenyamuhammad lutfiNo ratings yet

- Biochemical Factors Associated With Mango Mealy Bug (Drosicha Mangiferae G.) Infestation in Different Mango Cultivars at Malda, West Bengal (India)Document10 pagesBiochemical Factors Associated With Mango Mealy Bug (Drosicha Mangiferae G.) Infestation in Different Mango Cultivars at Malda, West Bengal (India)Shailendra RajanNo ratings yet

- Knowledge Level of Farmers On Agricultural Wastes Utilization in South West NigeriaDocument9 pagesKnowledge Level of Farmers On Agricultural Wastes Utilization in South West NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mango Value Chain Analysis The Case of Boloso Bombe Woreda, Wolaita EthiopiaDocument21 pagesMango Value Chain Analysis The Case of Boloso Bombe Woreda, Wolaita Ethiopiamulejimma100% (1)

- MangosDocument10 pagesMangosEdilsonGiraldoNo ratings yet

- A Detailed Review On Common Causes of Postharvest Loss and Quality Deterioration of Fruits and Vegetables in EthiopiaDocument5 pagesA Detailed Review On Common Causes of Postharvest Loss and Quality Deterioration of Fruits and Vegetables in Ethiopiamuluneh bekeleNo ratings yet

- Assessment of Fruit and Vegetable Waste at Wholesale Markets in Nepal For VermicompostingDocument9 pagesAssessment of Fruit and Vegetable Waste at Wholesale Markets in Nepal For Vermicompostingijr_journalNo ratings yet

- 456Document46 pages456Glydel De Guzman100% (1)

- 09 RK VishwakarmaDocument13 pages09 RK VishwakarmaM. Bayu MarioNo ratings yet

- Value Chain Analysis Faba Bean in The Central Highlands of Amhara Region Ethiopia The Case of Bassonawerana and TarimabeDocument11 pagesValue Chain Analysis Faba Bean in The Central Highlands of Amhara Region Ethiopia The Case of Bassonawerana and TarimabeNafolNo ratings yet

- Agrosearch (2013) 13 No.3: 242 - 255Document14 pagesAgrosearch (2013) 13 No.3: 242 - 255Nyemaigbani VictoryNo ratings yet

- The Banana Postharvest Value Chain AnalyDocument14 pagesThe Banana Postharvest Value Chain Analyagung dirgantaraNo ratings yet

- Consumers Awareness On Their Basic Rights and WilDocument15 pagesConsumers Awareness On Their Basic Rights and Wilkidabiy99No ratings yet

- Truncatus (Horn, Coleoptera: Bostrichidae), Are An Increasingly Important Constraint of FoodDocument5 pagesTruncatus (Horn, Coleoptera: Bostrichidae), Are An Increasingly Important Constraint of FoodAbraha AbadiNo ratings yet

- Successful Community-Based Management of Banana Wilt Caused by Fusarium Oxysporum F.sp. Cubense Tropical Race-4 Through ICAR-FUSICONTDocument5 pagesSuccessful Community-Based Management of Banana Wilt Caused by Fusarium Oxysporum F.sp. Cubense Tropical Race-4 Through ICAR-FUSICONTShailendra RajanNo ratings yet

- Mango Phenology and Fruit Fly Population DynamicsDocument11 pagesMango Phenology and Fruit Fly Population Dynamicsrr.almiralndwNo ratings yet

- Assessing The Potential Economic Impact of Bacillus Thuringiensis (BT) Maize in KenyaDocument11 pagesAssessing The Potential Economic Impact of Bacillus Thuringiensis (BT) Maize in KenyaTasnim MahinNo ratings yet

- Socio-Economic Factors Influencing The Use of Botanicals in Cocoa Pest ManagementDocument7 pagesSocio-Economic Factors Influencing The Use of Botanicals in Cocoa Pest ManagementAfolabi adisaNo ratings yet

- Resource Efficiency and Profitability in Yam Production Amongst Small Scale Yam Farmers in IMO State, NigeriaDocument12 pagesResource Efficiency and Profitability in Yam Production Amongst Small Scale Yam Farmers in IMO State, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- IDM Late Blight - 2016Document8 pagesIDM Late Blight - 2016Abebe ChindiNo ratings yet

- Impact of Improved Sorghum Variety (Melkam) A Doption On Smallholder Farmers Food Security in Babile District, Eastern EthiopiaDocument18 pagesImpact of Improved Sorghum Variety (Melkam) A Doption On Smallholder Farmers Food Security in Babile District, Eastern EthiopiaCrystal LoganNo ratings yet

- Economic Analysis of Commercial Banana Cultivation and Supply Chain Analysis in Chitwan, NepalDocument6 pagesEconomic Analysis of Commercial Banana Cultivation and Supply Chain Analysis in Chitwan, NepalKaran ShresthaNo ratings yet

- 1 s2.0 S0924224418303704 MainDocument12 pages1 s2.0 S0924224418303704 Mainayuw82212No ratings yet

- Sustainable Production of Banana, Musa Acuminata × Balbisiana Colla (ABB Group) CV Cardaba' Through Integrated Crop ManagementDocument9 pagesSustainable Production of Banana, Musa Acuminata × Balbisiana Colla (ABB Group) CV Cardaba' Through Integrated Crop ManagementMd Ashikur Rahman100% (1)

- Integrated Pest Management (IPM) farmer Field School (FFS): A Guide for Facilitators of FFS on Maize with Special Emphasis on Fall ArmywormFrom EverandIntegrated Pest Management (IPM) farmer Field School (FFS): A Guide for Facilitators of FFS on Maize with Special Emphasis on Fall ArmywormNo ratings yet

- Citrus Fruit: Biology, Technology and EvaluationFrom EverandCitrus Fruit: Biology, Technology and EvaluationRating: 3.5 out of 5 stars3.5/5 (2)

- Solar Based Multilevel Inverter f o r BLDC Motor DriveDocument8 pagesSolar Based Multilevel Inverter f o r BLDC Motor DriveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unlocking Sentiments: Enhancing IOCL Petrol Pump ExperiencesDocument8 pagesUnlocking Sentiments: Enhancing IOCL Petrol Pump ExperiencesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Potential Advantages of Traditional Therapies in Autoimmune Blistering Illnesses: A Comprehensive Review and Analysis, ResearchDocument12 pagesExploring the Potential Advantages of Traditional Therapies in Autoimmune Blistering Illnesses: A Comprehensive Review and Analysis, ResearchInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart and Secure Home with ChatbotDocument9 pagesSmart and Secure Home with ChatbotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Meta Land: Redefining Virtual Communities through Centralized Governance, Inclusivity and InnovationDocument5 pagesMeta Land: Redefining Virtual Communities through Centralized Governance, Inclusivity and InnovationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Seasonal Variation and Distribution Patterns of Endophytic Community in Withania somniferaDocument7 pagesSeasonal Variation and Distribution Patterns of Endophytic Community in Withania somniferaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Skin Disease Detection and Remedial SystemDocument7 pagesSkin Disease Detection and Remedial SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Development of Multi-Featured Medical StretcherDocument4 pagesDesign and Development of Multi-Featured Medical StretcherInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Global Warming Reduction Proposal AssessmentDocument6 pagesGlobal Warming Reduction Proposal AssessmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Development of Smart Ground Fault Location Model for Radial Distribution SystemDocument14 pagesDevelopment of Smart Ground Fault Location Model for Radial Distribution SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- EmoConnect: Nurturing Trust and Relationship Bonds in Alzheimer’s ConversationsDocument3 pagesEmoConnect: Nurturing Trust and Relationship Bonds in Alzheimer’s ConversationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Preparation and Identification of Magnetic Iron Nanoparticle based on a Natural Hydrogel and its Performance in Targeted Drug DeliveryDocument17 pagesPreparation and Identification of Magnetic Iron Nanoparticle based on a Natural Hydrogel and its Performance in Targeted Drug DeliveryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Firm Size as a Mediator between Inventory Management Andperformance of Nigerian CompaniesDocument8 pagesFirm Size as a Mediator between Inventory Management Andperformance of Nigerian CompaniesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of Plant Growth Promoting Rhizobacteria on Vegetative Growth in Chili Plants (Capsicum frutescens L.)Document7 pagesApplication of Plant Growth Promoting Rhizobacteria on Vegetative Growth in Chili Plants (Capsicum frutescens L.)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Reading Intervention Through “Brigada Sa Pagbasa”: Viewpoint of Primary Grade TeachersDocument3 pagesReading Intervention Through “Brigada Sa Pagbasa”: Viewpoint of Primary Grade TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- On the Development of a Threat Driven Model for Campus NetworkDocument14 pagesOn the Development of a Threat Driven Model for Campus NetworkInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- PHREEQ C Modelling Tool Application to Determine the Effect of Anions on Speciation of Selected Metals in Water Systems within Kajiado North Constituency in KenyaDocument71 pagesPHREEQ C Modelling Tool Application to Determine the Effect of Anions on Speciation of Selected Metals in Water Systems within Kajiado North Constituency in KenyaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring the Post-Annealing Influence on Stannous Oxide Thin Films via Chemical Bath Deposition Technique: Unveiling Structural, Optical, and Electrical DynamicsDocument7 pagesExploring the Post-Annealing Influence on Stannous Oxide Thin Films via Chemical Bath Deposition Technique: Unveiling Structural, Optical, and Electrical DynamicsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Osho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)Document8 pagesOsho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)International Journal of Innovative Science and Research TechnologyNo ratings yet