Professional Documents

Culture Documents

Targeted Drug Delivery Through The Synthesis of Magnetite Nanoparticle by Co-Precipitation Method and Creating A Silica Coating On It

Targeted Drug Delivery Through The Synthesis of Magnetite Nanoparticle by Co-Precipitation Method and Creating A Silica Coating On It

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Targeted Drug Delivery Through The Synthesis of Magnetite Nanoparticle by Co-Precipitation Method and Creating A Silica Coating On It

Targeted Drug Delivery Through The Synthesis of Magnetite Nanoparticle by Co-Precipitation Method and Creating A Silica Coating On It

Copyright:

Available Formats

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

Targeted Drug Delivery through the Synthesis of

Magnetite Nanoparticle by Co-Precipitation

Method and Creating a Silica Coating on it

Vahid Hosseini1; Seyed Masoud Ghoreishi Mokri2; Kadomtseva Alena Viktorovna3

1

Dentistry student at Privolzhsky Research Medical University, Nizhny Novgorod, Russia

2

Department of Medicine at Privolzhsky Research Medical University, Nizhny Novgorod, Russia

3

Associate Professor of the Department of General Chemistry at the Federal State Budgetary

Educational Institution of Higher Education "PIMU" of the Ministry of Health of Russia

Abstract:- Billions of dollars are spent annually in the ligands to the surface due to their tendency to create multiple

world to treat and investigate problems caused by drug covalent bonds. Other characteristics of nanoparticles include

side effects. According to the estimation of health chemical and biological stability, the ability to bind to both

researchers, a huge part of people who take medicine hydrophilic and hydrophobic drugs, and the ability to be

suffer from complications caused by it. In this way, the administered by different routes such as oral, inhalation, and

necessity of using a targeted system in order to deliver injection [1] These nanoparticles have the ability to carry

medicine to the targeted place without damaging healthy substances such as drugs in the form of dissolved, trapped,

tissues is felt more than before. In recent years, targeted encapsulated or attached to the nanoparticle matrix [2].

drug delivery systems based on nanoparticles have

received much attention. In the same direction, in this A group of nanoparticles that have an inorganic origin

research, co-precipitation method was used to prepare and are widely used in drug delivery systems are magnetic

magnetic nanoparticles using iron(|) and iron(||) oxides, iron nanoparticles that are chemically or biologically

and further, according to the synthesis steps of magnetite synthesized. Due to their magnetic properties, these particles

nanoparticles (MNPs) and the mechanism of formation can be directed to a specific place in the body by an external

and identification of magnetite nanoparticles ( Fe₃O₄) by magnetic field, therefore they are very useful and valuable in

examining the infrared pattern (FT-IR) obtained from the field of targeted drug delivery. From this category, we can

Fe₃O₄ nanoparticles, the results of the magnetometric test mention magnetite and maghemite nanoparticles, which have

(VSM) of Fe₃O₄ nanoparticles, X-ray diffraction pattern received a lot of attention in drug delivery. One of the most

(XRD) of Fe₃O₄ nanoparticles, Field Emission Scanning important advantages of magnetic nanoparticles is that they

Electron Microscope (FE-SEM) images obtained from can be easily modified [3].

Fe₃O₄ nanoparticles was discussed. After this stage, silica-

coated iron nanoparticles (Fe₃O₄@SiO₂) were prepared, In recent years, many methods have been designed and

and the infrared (FT-IR) pattern of Fe₃O₄@SiO₂) was also introduced for the production of magnetic nanoparticles, and

investigated. It is worth mentioning that the mechanism in most of them, the focus is on obtaining a controlled shape,

of formation and identification of magnetic silica-coated high stability and size of nanoparticles. The method used for

iron nanoparticles (Fe₃O₄@SiO₂) has been described in the synthesis of magnetic nanoparticles depends on the type

detail. Therefore, the obtained results indicate that the of properties of the desired material, which can be chosen

drug can be guided in a controlled and targeted manner after determining the properties of the desired product

by the magnetic field, and the results of the FE-SEM according to the shape, distribution and economic aspects.

images show that the obtained product has a spherical Among the methods that have been designed so far, we can

morphology and the particle size distribution was less mention the sol-gel method 5, co-precipitation, hydrothermal,

than 100 nm. Therefore, spherical shape and the combustion, sonochemical and microemulsion methods [4-

symmetry of these particles can be helpful for their 5].

movement in the liquid mediu.

II. CO-PRECIPITATION METHOD TO PREPARE

MAGNETIC NANOPARTICLES

Keywords:- Targeted Drug Delivery - Magnetite

Nanoparticle - Co-Precipitation Method - Silica Coating It is one of the oldest methods of synthesis of magnetic

nanoparticles, which was used for the first time to produce

I. INTRODUCTION magnetite nanoparticles. Among the advantages of this

method, it can be mentioned that it is a single step, easy, cost-

In general definition, it can be said that the particles of effective and fast, which produces a small and uniform

sizes in the range of (10-100) nanometers are called product. In this method, iron(Ⅱ) and iron(Ⅲ) oxides and a

nanoparticles. Nanoparticles, due to their very small size and base are used and magnetite nanoparticles can be synthesized.

high surface-to-volume ratio, can be used to attach multiple Among the effective parameters in the production of these

IJISRT24APR201 www.ijisrt.com 113

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

nanoparticles, we can mention the ionic strength, the type of (Ⅲ) ions, which are effective in the size, shape and

salt used, the reaction temperature, pH, the speed of stirring composition of the synthesized nanoparticles [6].

the reaction and adding base, and the ratio of iron (Ⅱ) and iron

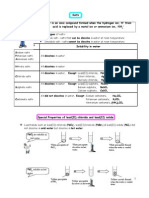

Steps of of Magnetite Nanoparticles (MNPs) Synthesis:

Co-precipitation method was used for the synthesis of III. MECHANISM OF FORMATION AND

nanoparticles in this research [7]. For this purpose, 4.5 grams IDENTIFICATION OF MAGNETITE

of FeCl₃.6H₂O and 2 grams of FeCl₂.4H₂O in 100 ml of NANOPARTICLES (FE₃O₄)

double-distilled water were added to a fume hood equipped

with nitrogen inlet and outlet, The resulting mixture was To prepare these nanoparticles, a co-precipitation

vigorously stirred with a magnetic stirrer under reflux method was used, in which iron (Ⅱ) and iron (Ⅲ) salts were

conditions and a temperature of 85°C for 15 minutes, then 15 used with stoichiometric ratios of 1 to 2 according to the

ml of 30% ammonia solution was added drop by drop to the following reaction:

mixture, the color of the mixture immediately changed from

orange to black. The resulting solution was refluxed for 30 By adding ammonia to the reaction solution containing

minutes. After the reaction is over, the precipitate was iron salts, spherical shape and black iron nanoparticles are

separated by a magnet and washed 3 times with double- obtained as follows.

distilled water. The black precipitate of Fe₃O₄ obtained from

this step was identified by FT-IR, VSM and SEM analyses

Fig 1: Magnetite preparation reaction

Fig 2: General Scheme of Preparation of Magnetite Nanoparticles

IJISRT24APR201 www.ijisrt.com 114

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

Magnetic iron nanoparticles are oxidized in air and prevent oxidation, nanoparticles were synthesized in the

produce Fe(OH)₃ according to the reaction shown below. To presence of nitrogen gas.

Examining the infrared pattern (FT-IR) of Fe₃O₄ increase of H, the amount of M increases until it reaches its

nanoparticles: highest level, which is called the saturation magnetization

Diagram 1- shows the FT-IR spectrum of the prepared (Ms). The resulting diagram shows a residual magnetic value

Fe₃O₄ compound. The two bands appearing at 430 Cm⁻¹and after removing the external field, which is called

560 Cm⁻¹correspond to the vibrations of the Fe—O bonds of "hysteresis loop ". The presence of this loop indicates that

the compound [8]. The band related to surface OH groups can after the removal of the external magnetic field, some

also be seen in the range of Cm⁻¹3400. magnetic property remains in the material and all the

magnetic property of the ferromagnetic material is not lost.

Because after the removal of the external magnetic field, the

orientation of the atomic magnetic moments in all areas do

not return to their original arrangement. Therefore, even when

the value of the external field H reaches zero, there is still

some residual magnetization MR in the material, which can

only be removed by applying a coercive HC field, opposite to

the initial field direction. In the magnetization diagram of

single-domain magnetic materials, no hysteresis loop is

observed, such compounds are called super-paramagnetic.

Magnetite nano-oxides smaller than 100 nm have

superparamagnetic properties at room temperature. [9]

Diagram 1: FT-IR Spectrum of Magnetite Nanoparticles

Examining the Results of the Magnetometery Test (VSM)

of Fe₃O₄ Nanoparticles:

In paramagnetic materials, the arrangement of atomic

magnetic moments is completely random and separate, so that

the magnetic moment of the entire crystal structure is zero. In

this case, if these materials are exposed to an external

magnetic field, some of these separate atomic magnetic

moments will find the same orientation and the structure will Fig 3: Changes of Magnetic Susceptibility in a

have a small amount of magnetic moment. In the Ferromagnetic Material

ferromagnetic state, the atomic magnetic moments have the

same orientation relative to each other. Therefore, the crystal Diagram 2- shows the magnetic behavior of magnetite

structure has a total magnetic moment. This is despite the fact nanoparticles, which was investigated by performing

that in an antiferromagnetic crystal, half of the atomic vibrational magnetometer analysis of the VSM sample. As

magnetic moments are directed upwards and the other half are can be seen, the obtained magnetite particles show the

directed downwards. Therefore, the total magnetic moment characteristic of super para magnetism with a maximum

for an antiferromagnetic crystal is zero. Figure 2 shows the magnetic susceptibility of 70 emu/g. The absence of a

magnetic susceptibility diagram of a ferromagnetic material hysteresis loop in the magnetic susceptibility diagram is a

with magnetic strength M in the presence of an external confirmation of the superparamagnetic behavior of magnetite

magnetic field with strength H. As it can be seen, with the in the presence of an external magnetic field.

IJISRT24APR201 www.ijisrt.com 115

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

Diagram 2: Magnetometric Diagram of Magnetite Nanoparticles

Examining the X-Ray Diffraction (XRD) Pattern of Fe₃O₄

Nanoparticles

The X-ray diffraction pattern of Fe₃O₄ compound is

shown in Figure 3. Comparing this pattern with the reference

magnetite pattern in the aforementioned device with JCPDS

No. 0629-19, which belongs to Fe₃O₄, determined that all the

diffraction signals related to the prepared magnetite structure

are consistent with the diffraction related to the reference

magnetite structure in terms of the position and intensity of

vibrations, which is a confirmation of the formation of the

Fe₃O₄ compound.

Fig 4: FESEM Images Obtained from Magnetite

Nanoparticles

Preparation of Silica Coated Iron Nanoparticles

(Fe₃O₄@SiO₂)

Silica coated iron nanoparticles were prepared with a

slight change according to the method of Liu et al. [10] In this

step, 3 grams of Fe₃O₄ nanoparticles obtained from the

previous step were transferred to a double-mouth flask and 80

ml of tetra ethyl ortho silicate (TEOS) solution 10% by

volume in deionized water was added to it. Then, 60 ml of

glycerol was added to the mixture and the pH of the resulting

suspension was adjusted by acetic acid to about 4.5. At the

Diagram 3: X-ray Diffraction Pattern of end, the resulting mixture was stirred under reflux at a

Magnetite Nanoparticles temperature of 90°C for 2 hours with a magnetic stirrer. At

the end, the resulting contents were transferred to a beaker,

Examining the Scanning Electron Microscope (FE-SEM) the sediment was separated by a magnet, and washed with

Images Obtained from Fe₃O₄ Nanoparticles double-distilled water and methanol, respectively. After

Scanning electron microscope is used to determine drying at room temperature, the resulting nanoparticles were

surface morphology, texture, size and shape of major samples identified by FT-IR spectroscopy.

of solid materials. The FE-SEM images obtained from the

Fe₃O₄ compound in this project are shown in Figure 3. As can Mechanism of Formation and Identification of Silica

be seen, the obtained nanoparticles are assemblies of Coated Magnetic Iron Nanoparticles (Fe₃O₄@SiO₂)

spherical particles stuck together with a high surface area and In order to prevent magnetite nanoparticles from

an approximate size of 20-30 nm. oxidizing, an inert layer of silica is placed between the iron

core and the reaction medium. It is possible to perform this

operation with the sol-gel technique and by adding the TEOS

compound to the solution containing magnetite nanoparticles

[11].

IJISRT24APR201 www.ijisrt.com 116

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

Among the effects of silicon coating on magnetite vibrations of the Si—O—Si bond, which appeared in the

nanoparticles, we can mention protecting them against range of Cm⁻¹980 and Cm⁻¹1080, respectively. [13] The

oxidation, creating a suitable space for modifying the surface broad band appearing in the range of Cm⁻¹3400 indicates the

of nanoparticles, and also increasing their thermal stability. presence of OH bonds on the surface of these nanoparticles

Another important advantage of this process is the increase in [14].

the number of hydroxyl groups on the surface of

nanoparticles, which causes better functionalization on the

surface of nanoparticles. Also, the silica coating prevents the

clumping of nanoparticles and the distribution of particles in

the solution environment is better [12].

The mechanism of this process is shown below in Figure

4. First, TEOS molecules are formed in the vicinity of glacial

acetic acid and glycerol hydrolysis, followed by hydroxyl

groups. Adding glycerol to the solution causes the

nanoparticles to be completely separated and the silica

coating is done more effectively. The reason for adding acid

is to adjust the pH of the solution in order to hydrolyze the

OH groups on the surface of nanoparticles and TEOS Diagram 4: FT-IR Spectrum of Magnetite Nanoparticles

molecules, and as a result, these molecules are effectively Coated with Silica

connected to each other. A scheme of silica coating process

on magnetite nanoparticles is shown in Figure 5: IV. CONCLUSIONS

In this research, an attempt has been made to provide a

method in which the medicine can be controlled and directed

by the magnetic field. The results of examining the FE-SEM

images show that the obtained product had a spherical

morphology and the particle size distribution was less than

100 nm. The spherical and symmetrical shape of these

particles can help them move in the liquid environment.

Analysis of the thermal decomposition of the final product

also indicates the presence of both organic and mineral

substances in the drug part and the magnetic part of the

Fig 5: Hydrolysis Mechanism of TEOS Molecules

sample.

REFERENCES

[1]. Masserini M. Nanoparticles for brain drug delivery.

International Scholarly Research Notices. 2013;2013.

[2]. Hamidi M, Azadi A, Rafiei P. Hydrogel nanoparticles

in drug delivery. Advanced drug delivery reviews.

2008 Dec 14;60(15):1638-49.

[3]. Arias JL, editor. Nanotechnology and drug delivery,

volume one: nanoplatforms in drug delivery. CRC

Press; 2014 Aug 4.

[4]. Kandpal ND, Sah N, Loshali R, Joshi R, Prasad J. Co-

precipitation method of synthesis and characterization

Fig 6: Schematic of the Silica Coating Process of

of iron oxide nanoparticles.

Magnetite Nanoparticles

[5]. Mascolo MC, Pei Y, Ring TA. Room temperature co-

precipitation synthesis of magnetite nanoparticles in a

Investigating the Infrared Pattern (FT-IR) Related to

large pH window with different bases. Materials. 2013

Fe₃O₄@SiO₂)

Nov 28;6(12):5549-67.

Diagram 4 is the FT-IR spectrum of silica coated

[6]. Hariani PL, Faizal M, Setiabudidaya D. Synthesis and

magnetite nanoparticles. All bands related to the previous

properties of Fe3O4 nanoparticles by co-precipitation

stage are observed in this spectrum. Vibrations related to

method to removal procion dye. International Journal

Fe—O bonds appeared in the range of Cm⁻¹460, which

of Environmental Science and Development. 2013 Jun

overlapped with the bands related to Fe—O—Si bonds

1;4(3):336.

located in this range. Therefore, the existence of a silicon

network on the surface of nanoparticles is proved by the

bands related to the symmetric and asymmetric stretching

IJISRT24APR201 www.ijisrt.com 117

Volume 9, Issue 4, April – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24APR201

[7]. Kim YI, Kim D, Lee CS. Synthesis and

characterization of CoFe2O4 magnetic nanoparticles

prepared by temperature-controlled coprecipitation

method. Physica B: Condensed Matter. 2003 Sep

1;337(1-4):42-51..

[8]. Kasapoğlu N, Baykal A, Köseoğlu Y, Toprak MS.

Microwave-assisted combustion synthesis of

CoFe2O4 with urea, and its magnetic characterization.

Scripta Materialia. 2007 Sep 1;57(5):441-4.

[9]. Teja AS, Koh PY. Synthesis, properties, and

applications of magnetic iron oxide nanoparticles.

Progress in crystal growth and characterization of

materials. 2009 Mar 1;55(1-2):22-45.

[10]. Liu X, Ma Z, Xing J, Liu H. Preparation and

characterization of amino–silane modified

superparamagnetic silica nanospheres. Journal of

Magnetism and magnetic Materials. 2004 Mar

1;270(1-2):1-6.

[11]. Saadati-Moshtaghin HR, Zonoz FM. Preparation and

characterization of magnetite-dihydrogen phosphate

as a novel catalyst in the synthesis of tetrahydrobenzo

[b] pyrans. Materials Chemistry and Physics. 2017

Sep 15;199:159-65.

[12]. Gill CS, Price BA, Jones CW. Sulfonic acid-

functionalized silica-coated magnetic nanoparticle

catalysts. Journal of Catalysis. 2007 Oct 1;251(1):145-

52.

[13]. Yamaura M, Camilo RL, Sampaio LC, Macêdo MA,

Nakamura M, Toma HE. Preparation and

characterization of (3-aminopropyl) triethoxysilane-

coated magnetite nanoparticles. Journal of magnetism

and magnetic materials. 2004 Aug 1;279(2-3):210-7.

[14]. Takami S, Sato T, Mousavand T, Ohara S, Umetsu M,

Adschiri T. Hydrothermal synthesis of surface-

modified iron oxide nanoparticles. Materials Letters.

2007 Oct 1;61(26):4769-72.

IJISRT24APR201 www.ijisrt.com 118

You might also like

- Ozonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationDocument25 pagesOzonation of Drinking Water - Part I. Oxidation Kinetics and Product FormationArif HidayatNo ratings yet

- Magnetic Nanoparticles ReviewDocument61 pagesMagnetic Nanoparticles ReviewramikNo ratings yet

- Cyanide Remediation: Current and Past TechnologiesDocument26 pagesCyanide Remediation: Current and Past TechnologiesCoraKiriNo ratings yet

- List of Steel Producer and Related AssociationsDocument2 pagesList of Steel Producer and Related Associationsbindu pathakNo ratings yet

- Inbound and Outbound Logistics SOPDocument34 pagesInbound and Outbound Logistics SOPFaysal AhmedNo ratings yet

- Synthesis and Processing of Magnetic Nan 2015 Current Opinion in Chemical enDocument8 pagesSynthesis and Processing of Magnetic Nan 2015 Current Opinion in Chemical enLuminita AndronicNo ratings yet

- Samrot 2020Document44 pagesSamrot 2020Ariel SaavNo ratings yet

- 1 s2.0 S221478532035344X MainDocument5 pages1 s2.0 S221478532035344X MainEsmeralda SouzaNo ratings yet

- Synthesis and Application of Magnetic Nanoparticles: OutlineDocument25 pagesSynthesis and Application of Magnetic Nanoparticles: OutlinesimoNo ratings yet

- Research Article: Preparation and Characterization of Promoted Fe-V/Sio Nanocatalysts For Oxidation of AlcoholsDocument11 pagesResearch Article: Preparation and Characterization of Promoted Fe-V/Sio Nanocatalysts For Oxidation of AlcoholsAhmed Fouad MusaNo ratings yet

- Synthesis and Characterization of Silver Nanoparticle by Chemical Route MethodDocument11 pagesSynthesis and Characterization of Silver Nanoparticle by Chemical Route MethodThasya Nurfadillah SiregarNo ratings yet

- Materials Research BulletinDocument8 pagesMaterials Research BulletinDeepaNo ratings yet

- Polymers: Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic CoatingsDocument28 pagesPolymers: Synthesis, Characterization, and Applications of Magnetic Nanoparticles Featuring Polyzwitterionic CoatingsAlameluValliNo ratings yet

- 14korean Chem 14Document5 pages14korean Chem 14prakashpaleiNo ratings yet

- 77 - Manuscript 608 2 10 20220107Document13 pages77 - Manuscript 608 2 10 20220107Laila BahriNo ratings yet

- Systematic Review of The Preparation Techniques of Iron Oxide Magnetic NanoparticlesDocument11 pagesSystematic Review of The Preparation Techniques of Iron Oxide Magnetic NanoparticlesSyed Farhan HasanyNo ratings yet

- Microwave-Assisted Synthesis of Mgfe O - Zno Nanocomposite and Its Photo-Catalyst Investigation in Methyl Orange DegradationDocument7 pagesMicrowave-Assisted Synthesis of Mgfe O - Zno Nanocomposite and Its Photo-Catalyst Investigation in Methyl Orange Degradationjawad AhmadNo ratings yet

- 10 1016@j Physe 2020 114291Document30 pages10 1016@j Physe 2020 114291Sri komalaNo ratings yet

- 8 JMSMathubalaDocument9 pages8 JMSMathubalaAshraf MouradNo ratings yet

- Barzinjy-Azeez2020 Article GreenSynthesisAndCharacterizatDocument14 pagesBarzinjy-Azeez2020 Article GreenSynthesisAndCharacterizatManal AwadNo ratings yet

- Review Article: Magnetic Nanoparticles: A Subject For Both Fundamental Research and ApplicationsDocument23 pagesReview Article: Magnetic Nanoparticles: A Subject For Both Fundamental Research and Applicationsprincetahir123No ratings yet

- Manganese Dioxide Nanoparticles: Synthesis, Application and ChallengesDocument10 pagesManganese Dioxide Nanoparticles: Synthesis, Application and ChallengesRajesh Kumar MishraNo ratings yet

- BactericidalEvaluationofNano coatedCottonFabrics HananlastPaperDocument9 pagesBactericidalEvaluationofNano coatedCottonFabrics HananlastPaperSawitchaya SinprommaNo ratings yet

- 1.5117079 (Ukuran MNP)Document11 pages1.5117079 (Ukuran MNP)Sari Ramadhani MeutuahNo ratings yet

- Monodisperse Magnetic Single-Crystal Ferrite MicrospheresDocument4 pagesMonodisperse Magnetic Single-Crystal Ferrite MicrospheresMahoo ShahNo ratings yet

- Ceramics International: Swapnil A. Jadhav, Mangesh V. Khedkar, Sandeep B. Somvanshi, K.M. JadhavDocument11 pagesCeramics International: Swapnil A. Jadhav, Mangesh V. Khedkar, Sandeep B. Somvanshi, K.M. JadhavJuancho PachonNo ratings yet

- Au-Fe3O4 Heterostructures For Catalytic, Analytical, and Biomedical ApplicationsDocument6 pagesAu-Fe3O4 Heterostructures For Catalytic, Analytical, and Biomedical ApplicationsPhú Nguyễn VĩnhNo ratings yet

- JI Pasir BesiDocument6 pagesJI Pasir BesiPrita YhuniNo ratings yet

- Behrad2015 Article SynthesisAndCharacterizationOfDocument9 pagesBehrad2015 Article SynthesisAndCharacterizationOfnida shahbazNo ratings yet

- Applyingasuitablerouteforpreparation Fe 3 O4 Nanoparticlesby AmmoniaandinvestigationoftheirphysicalanddifferentmagneticpropertiesDocument9 pagesApplyingasuitablerouteforpreparation Fe 3 O4 Nanoparticlesby AmmoniaandinvestigationoftheirphysicalanddifferentmagneticpropertiesGurudas VisputeNo ratings yet

- Methods: Adelina-Gabriela Niculescu, Cristina Chircov, Alexandru Mihai GrumezescuDocument12 pagesMethods: Adelina-Gabriela Niculescu, Cristina Chircov, Alexandru Mihai GrumezescuMaría Pía Arancibia BravoNo ratings yet

- Rashmi 2017Document48 pagesRashmi 2017JAY BHARATBHAI LAKHANINo ratings yet

- Synthesis of Magnesium Oxide Nanoparticles From Pterocarpus Marsupium Rox.b Heartwood ExtractDocument18 pagesSynthesis of Magnesium Oxide Nanoparticles From Pterocarpus Marsupium Rox.b Heartwood ExtractVũ Phi YếnNo ratings yet

- Journal of Environmental Chemical Engineering: M. Sivakami, K. Renuka Devi, R. Renuka, T. ThilagavathiDocument11 pagesJournal of Environmental Chemical Engineering: M. Sivakami, K. Renuka Devi, R. Renuka, T. ThilagavathiHiramAmaroNo ratings yet

- Magnetic and Transient Temperature Field Simulation of Plate-Plate Magnetorheometer Using Finite Element MethodDocument9 pagesMagnetic and Transient Temperature Field Simulation of Plate-Plate Magnetorheometer Using Finite Element Methodbittu singhNo ratings yet

- Introduction To Nanomaterials - 240122 - 213807Document13 pagesIntroduction To Nanomaterials - 240122 - 213807Luis Enrique Gomez MorenoNo ratings yet

- Photostability, CytotoxicityDocument13 pagesPhotostability, CytotoxicityTeólogo PolifacéticoNo ratings yet

- Silver Nanoparticles PDFDocument19 pagesSilver Nanoparticles PDFGet BusyNo ratings yet

- Synthesis and Characterization of Magnetic Nanoparticles Using Polyvinylpirrolidone As StabilizerDocument5 pagesSynthesis and Characterization of Magnetic Nanoparticles Using Polyvinylpirrolidone As Stabilizerjose maría MoncayoNo ratings yet

- Literature Review On Synthesis of Zno Nano Particles Using Natural and Synthetic MethodsDocument6 pagesLiterature Review On Synthesis of Zno Nano Particles Using Natural and Synthetic Methodsaashi kapoorNo ratings yet

- Ultra 3Document6 pagesUltra 3Raj RajNo ratings yet

- Synthesis and Characterization of Nickel Doped Cobalt Ferrites by Precipitation MethodDocument27 pagesSynthesis and Characterization of Nickel Doped Cobalt Ferrites by Precipitation Methodনিউটন নিয়োগীNo ratings yet

- Ijer 2014 423Document7 pagesIjer 2014 423Innovative Research PublicationsNo ratings yet

- Influence of MWCNTs On The FormationDocument6 pagesInfluence of MWCNTs On The FormationLuis Alberto Romero OrellanaNo ratings yet

- Silver Nanoparticles: Hassan Korbekandi Siavash IravaniDocument35 pagesSilver Nanoparticles: Hassan Korbekandi Siavash IravaniVILEOLAGOLDNo ratings yet

- Mahi ProjectDocument55 pagesMahi ProjectMahizhaNo ratings yet

- 2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorization, PDFDocument48 pages2064-2110 - Magnetic Iron Oxide Nanoparticles - Synthesis, Stabilization, Vectorization, PDFRoxana Cristina PopescuNo ratings yet

- Synthesis and Characterization of Magnetite Nanoparticles Via The Chemical Co Precipitation MethodDocument4 pagesSynthesis and Characterization of Magnetite Nanoparticles Via The Chemical Co Precipitation MethodAkef AfanehNo ratings yet

- 10.JCPR 7 9S 139 146rahmayeni2015Document9 pages10.JCPR 7 9S 139 146rahmayeni2015mdiaz_784526No ratings yet

- 2014 - A Facile Thermal-Treatment Route To SynthesizeDocument9 pages2014 - A Facile Thermal-Treatment Route To SynthesizeMoayad FlaifelNo ratings yet

- Vol-1, Issue-4Document3 pagesVol-1, Issue-4Ijrei JournalNo ratings yet

- Review Article: Biosynthesis of Silver Nanoparticles and Its ApplicationsDocument19 pagesReview Article: Biosynthesis of Silver Nanoparticles and Its ApplicationshameedhaaNo ratings yet

- Green NanoDocument6 pagesGreen NanohatijabanuNo ratings yet

- 10 1016j Seppur 2017 05 007Document13 pages10 1016j Seppur 2017 05 007Aulia Sukma HutamaNo ratings yet

- Journal of Alloys and Compounds: SciencedirectDocument9 pagesJournal of Alloys and Compounds: SciencedirectjuansanninNo ratings yet

- Magnetic NanoparticlesDocument6 pagesMagnetic NanoparticlesSebas TianNo ratings yet

- Sogel Synthesi of Copper Oxide Nano ParticlesDocument3 pagesSogel Synthesi of Copper Oxide Nano ParticlesThe PhysicistsNo ratings yet

- High Mag Moment Table - Appl. Sci. 2022, 12, 1899Document10 pagesHigh Mag Moment Table - Appl. Sci. 2022, 12, 1899Tania ChatterjeeNo ratings yet

- 1 s2.0 S2666523921001094 MainDocument17 pages1 s2.0 S2666523921001094 MainWidya Edi Sekar AyuNo ratings yet

- Structural and Magnetic Properties of Mesoporous Sio Nanoparticles Impregnated With Iron Oxide or Cobalt-Iron Oxide NanocrystalsDocument13 pagesStructural and Magnetic Properties of Mesoporous Sio Nanoparticles Impregnated With Iron Oxide or Cobalt-Iron Oxide NanocrystalsConstantin DenisaNo ratings yet

- The Preparation of Magnetic Nanoparticles For Applications in BiomedicineDocument17 pagesThe Preparation of Magnetic Nanoparticles For Applications in BiomedicineMadavat Prem Pai LópezNo ratings yet

- Journal of Magnetism and Magnetic Materials: M.M. Rashad, D.A. Rayan, A.O. Turky, M.M. HessienDocument8 pagesJournal of Magnetism and Magnetic Materials: M.M. Rashad, D.A. Rayan, A.O. Turky, M.M. HessienSajjad HasanNo ratings yet

- Synthesis, Characterization, and Applications of Copper NanoparticlesDocument14 pagesSynthesis, Characterization, and Applications of Copper NanoparticlesardianNo ratings yet

- Nanocomposites: In Situ Synthesis of Polymer-Embedded NanostructuresFrom EverandNanocomposites: In Situ Synthesis of Polymer-Embedded NanostructuresLuigi NicolaisNo ratings yet

- Human Resource Functions: Examining Insights from ABC Research OrganizationDocument9 pagesHuman Resource Functions: Examining Insights from ABC Research OrganizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Conceptualized Fusion Reactor based on Gas Turbine with High Temperature CO2Document7 pagesConceptualized Fusion Reactor based on Gas Turbine with High Temperature CO2International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Expanding Attack Surface: Securing AI and Machine Learning Systems in Security OperationsDocument8 pagesThe Expanding Attack Surface: Securing AI and Machine Learning Systems in Security OperationsInternational Journal of Innovative Science and Research Technology100% (1)

- Personal Capabilities of The Non-Teaching Personnel and Client SatisfactionDocument8 pagesPersonal Capabilities of The Non-Teaching Personnel and Client SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of the Commercial Agriculture Credit Scheme (CACS) on the Agricultural Economy of Nigeria and its Total Output (2015-2019)Document8 pagesThe Impact of the Commercial Agriculture Credit Scheme (CACS) on the Agricultural Economy of Nigeria and its Total Output (2015-2019)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Teacher-Induced Academic Stress: Predicting Eating Behavior Problems in College StudentsDocument8 pagesTeacher-Induced Academic Stress: Predicting Eating Behavior Problems in College StudentsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Modern Approaches to Sustainable AgricultureDocument10 pagesModern Approaches to Sustainable AgricultureInternational Journal of Innovative Science and Research Technology100% (1)

- Integrating Quantum Algorithms with Gravitational-Wave Metrology for Enhanced Signal DetectionDocument18 pagesIntegrating Quantum Algorithms with Gravitational-Wave Metrology for Enhanced Signal DetectionInternational Journal of Innovative Science and Research Technology100% (1)

- Utilizing Chicken Eggshells and Waste Glass Powder as Cement Fillers for Environmental StabilityDocument6 pagesUtilizing Chicken Eggshells and Waste Glass Powder as Cement Fillers for Environmental StabilityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Termite Activity on the Availability of Soil Micronutrients in Tropical RegionsDocument6 pagesThe Impact of Termite Activity on the Availability of Soil Micronutrients in Tropical RegionsInternational Journal of Innovative Science and Research Technology100% (1)

- Assessment of Integrated Poultry Manure and Synthetic Fertilizer Effects on Maize (Zea mays) Growth and Soil Properties: A Study from Bayero University, KanoDocument15 pagesAssessment of Integrated Poultry Manure and Synthetic Fertilizer Effects on Maize (Zea mays) Growth and Soil Properties: A Study from Bayero University, KanoInternational Journal of Innovative Science and Research Technology100% (1)

- Study of prevalence of Head Lice (Pediculus Humanus Capitis) Among Schoolchildren in the Zawiya Region, LibyaDocument10 pagesStudy of prevalence of Head Lice (Pediculus Humanus Capitis) Among Schoolchildren in the Zawiya Region, LibyaInternational Journal of Innovative Science and Research Technology0% (1)

- Transforming Challenges to Victories: An Inquiry on Transformational Leadership of School Leaders in the Public Elementary SchoolsDocument54 pagesTransforming Challenges to Victories: An Inquiry on Transformational Leadership of School Leaders in the Public Elementary SchoolsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Meta Land: Redefining Virtual Communities Through Centralized Governance, Inclusivity and InnovationDocument5 pagesMeta Land: Redefining Virtual Communities Through Centralized Governance, Inclusivity and InnovationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Development of Smart Ground Fault Location Model For Radial Distribution SystemDocument14 pagesDevelopment of Smart Ground Fault Location Model For Radial Distribution SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Solar Based Multilevel Inverter F o R BLDC Motor DriveDocument8 pagesSolar Based Multilevel Inverter F o R BLDC Motor DriveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Development of Multi-Featured Medical StretcherDocument4 pagesDesign and Development of Multi-Featured Medical StretcherInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Influence of Continuance Commitment on Job Satisfaction of Barangay Health Workers in Malaybalay City, BukidnonDocument14 pagesThe Influence of Continuance Commitment on Job Satisfaction of Barangay Health Workers in Malaybalay City, BukidnonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Seasonal Variation and Distribution Patterns of Endophytic Community in Withania SomniferaDocument7 pagesSeasonal Variation and Distribution Patterns of Endophytic Community in Withania SomniferaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exploring The Potential Advantages of Traditional Therapies in Autoimmune Blistering Illnesses: A Comprehensive Review and Analysis, ResearchDocument12 pagesExploring The Potential Advantages of Traditional Therapies in Autoimmune Blistering Illnesses: A Comprehensive Review and Analysis, ResearchInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intelligent Clinical Documentation: Harnessing Generative AI For Patient-Centric Clinical Note GenerationDocument15 pagesIntelligent Clinical Documentation: Harnessing Generative AI For Patient-Centric Clinical Note GenerationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Strategic Deployment of Ducklink Wireless Devices For Disaster Mitigation and Management in Nueva ECIJA University of Science and Technology Sumacab CampusDocument13 pagesStrategic Deployment of Ducklink Wireless Devices For Disaster Mitigation and Management in Nueva ECIJA University of Science and Technology Sumacab CampusInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Skin Disease Detection and Remedial SystemDocument7 pagesSkin Disease Detection and Remedial SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of Plant Growth Promoting Rhizobacteria On Vegetative Growth in Chili Plants (Capsicum Frutescens L.)Document7 pagesApplication of Plant Growth Promoting Rhizobacteria On Vegetative Growth in Chili Plants (Capsicum Frutescens L.)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Reading Intervention Through "Brigada Sa Pagbasa": Viewpoint of Primary Grade TeachersDocument3 pagesReading Intervention Through "Brigada Sa Pagbasa": Viewpoint of Primary Grade TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unlocking Sentiments: Enhancing IOCL Petrol Pump ExperiencesDocument8 pagesUnlocking Sentiments: Enhancing IOCL Petrol Pump ExperiencesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- EmoConnect: Nurturing Trust and Relationship Bonds in Alzheimer's ConversationsDocument3 pagesEmoConnect: Nurturing Trust and Relationship Bonds in Alzheimer's ConversationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fall Detection and Boundary Detection in Care HomesDocument7 pagesFall Detection and Boundary Detection in Care HomesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart and Secure Home With ChatbotDocument9 pagesSmart and Secure Home With ChatbotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Preparation and Identification of Magnetic Iron Nanoparticle Based On A Natural Hydrogel and Its Performance in Targeted Drug DeliveryDocument17 pagesPreparation and Identification of Magnetic Iron Nanoparticle Based On A Natural Hydrogel and Its Performance in Targeted Drug DeliveryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 10 Social Science Geography Manufacturing Industries Key 1 EngDocument2 pages10 Social Science Geography Manufacturing Industries Key 1 EngSiddharth Jain100% (1)

- Coefficient of Friction Reference Table - Engineer's HandbookDocument5 pagesCoefficient of Friction Reference Table - Engineer's HandbookMinhddNo ratings yet

- José Henrique Noldin Júnior - Trends in Iron-Making Given The New Reality of Ore and Coal ResourcesDocument34 pagesJosé Henrique Noldin Júnior - Trends in Iron-Making Given The New Reality of Ore and Coal Resourcesagilan89No ratings yet

- Training Cooling Tower Treatment ChemicalsDocument127 pagesTraining Cooling Tower Treatment ChemicalsparagNo ratings yet

- 12 Modul of Pahang For RedoxDocument37 pages12 Modul of Pahang For RedoxkhayranizamNo ratings yet

- Chemistry CHP Ter 8Document21 pagesChemistry CHP Ter 8IZIKNo ratings yet

- A-14-03772 KMST 002 StellramCuttingTools en MeDocument732 pagesA-14-03772 KMST 002 StellramCuttingTools en Mevideo12No ratings yet

- Choose The Letter of The Correct Answer. Write Your Answer in Your Answer SheetsDocument2 pagesChoose The Letter of The Correct Answer. Write Your Answer in Your Answer SheetsKIMNo ratings yet

- TRELLEBORG - Mechanical-Face-Seals-EnDocument27 pagesTRELLEBORG - Mechanical-Face-Seals-EnMax SalogniNo ratings yet

- Fact Sheet Scrap Use in The Steel IndustryDocument2 pagesFact Sheet Scrap Use in The Steel IndustryrezaNo ratings yet

- Christopher Design Building ProjectDocument13 pagesChristopher Design Building ProjectMrSamspartNo ratings yet

- Cambridge IGCSE: Chemistry 0620/22Document16 pagesCambridge IGCSE: Chemistry 0620/22Tilawat KhanNo ratings yet

- 1 Lecture Metallogenic Zones in PakistanDocument74 pages1 Lecture Metallogenic Zones in PakistanFawad AhmedNo ratings yet

- LC Series Oval Gear Flow MeterDocument6 pagesLC Series Oval Gear Flow MeterGuillermo RoblesNo ratings yet

- Incoloy 800 / Alloy 800 / UNS N08800 / DIN 1.4876Document3 pagesIncoloy 800 / Alloy 800 / UNS N08800 / DIN 1.4876SamkitNo ratings yet

- Important Questions Class 10 Science Chapter 1Document21 pagesImportant Questions Class 10 Science Chapter 1Darshuram DudheNo ratings yet

- Carbon / Sulfur Analyzer: Elementrac CS-iDocument16 pagesCarbon / Sulfur Analyzer: Elementrac CS-iSoumitra BhowmikNo ratings yet

- A Practical Engineering Approach To Improving The Reability of Blast Furnace TuyeresDocument16 pagesA Practical Engineering Approach To Improving The Reability of Blast Furnace TuyeresGabriel MáximoNo ratings yet

- Emissivity Table For Thermal ImagerDocument18 pagesEmissivity Table For Thermal ImagerMarc Winston A. LaygoNo ratings yet

- J. Nutr.-1963-Consolazio-407-15Document9 pagesJ. Nutr.-1963-Consolazio-407-15azuredreamNo ratings yet

- Describing ObjectDocument5 pagesDescribing ObjectadamNo ratings yet

- Alunite-Jarosite Crystallography, Thermodynamics, and GeochronologyDocument27 pagesAlunite-Jarosite Crystallography, Thermodynamics, and GeochronologyMarshel EmmanuelleNo ratings yet

- Inorganic Chap#3 And#4 Hom Take ExamDocument22 pagesInorganic Chap#3 And#4 Hom Take Examwold100% (1)

- Skema BK2 KimiaDocument12 pagesSkema BK2 KimiaazmiNo ratings yet

- Bomba Peerless PDFDocument12 pagesBomba Peerless PDFzepol051No ratings yet

- Lecture01 - Hubert - Comm - Glasses - and Raw - Matls PDFDocument87 pagesLecture01 - Hubert - Comm - Glasses - and Raw - Matls PDFyacineNo ratings yet