Well, I figure I've started hacking and wacking at the challenge car, so it's about time to spill the beans on our project. It's a project that I've been accumulating parts for over a few years and wasn't originally planned to be a $200X project, but about a year ago (when the $2009 was planned for the West Coast) I decided it made sense to give it a whack since my basic parts could fit in the budget and a deadline would force me to get it done! Here's the skinny on the big parts of the build:

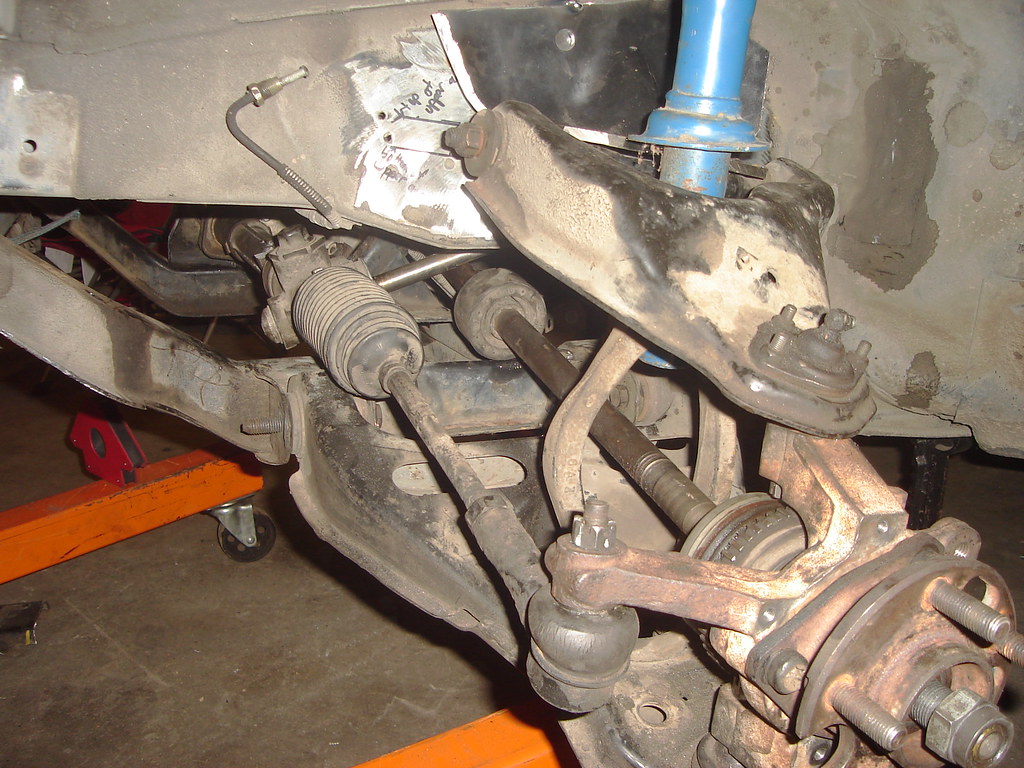

'88 Fiero Formula - I'm a craigslist hound and this is one of my "Look what I found!" trophies. I paid $500 for it because the owner thought it needed the engine rebuilt and had torn the top of the engine off. A few bucks for a used ignition module and a few hours of reassembly later and I had a fully functioning Formula on my hands. I chose a Fiero because it accepts a second transverse drivetrain fairly easily, it's a unique American car, it is GM (to match the motor), and I just plain like Fieros.

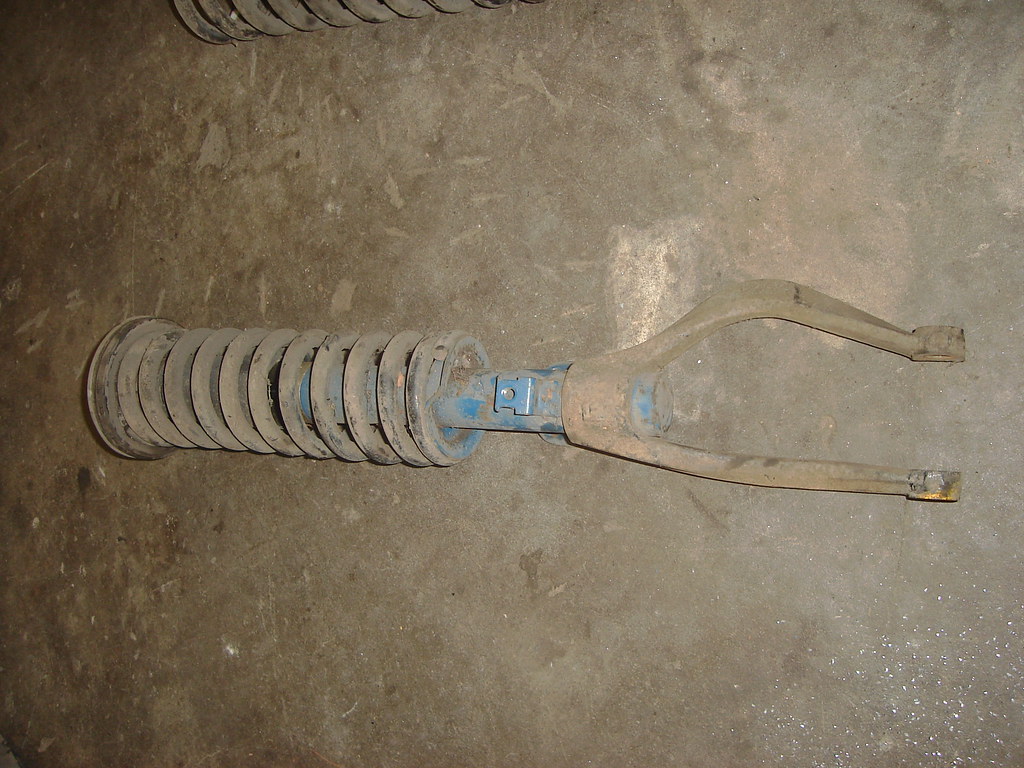

S10 Electric motor and inverter - The heart and soul of the project. This was sort-of an ebay find. Schram's is a big junkyard in MI known for getting lots of neat stuff from the OEMs in the area, especially GM. They had an ebay ad for an even more complete motor/inverter/wiring package from an electric S10 that a friend of mine got. When he picked it up at Schram's, they said they had two more on hand that weren't quite as complete. By the time I called (the next day) they only had one inverter and motor left. I paid $800 for the package shipped to my door. The motor is originally rated at 85kW. If you haven't heard of the S10 electric, it uses a motor/inverter that was just like the one in the EV1.

Prius batteries - I've been accumulating Prius batteries to power the electric motor. The Prius packs in stock form don't put out the kind of voltage I need, but they're very flexible designs so I can make my own packs by dissecting the packs and reassembling the modules to get the voltage I need. I can use more or less packs as I want for more or less range, power, etc. The going rate on Prius packs is averaging about $250 each, and I can use as few as two (actually 1.5).

The idea is to make an AWD Fiero hybrid. I can use it as an EV only for short ranges, gas only for long range driving, or hybrid for maximum power and performance. At first glance, this seems like a hell of a complex build, but I'm optimistic that some parts bin scrounging and plenty of digging around on the internet will make it happen. I'm hoping to show you Florida-bound folks that we West Coasters have something fresh to bring to the table and also hope to bring attention to budget electric stuff that is fun. There are a lot of people that build cheap EVs out there, but they usually involve things like Geos with forklift motors that can't go fast enough to get on the highway and people tend to scoff at them. Cheap EVs don't have to be slow and boring!

Bryce