These Superjets are the first passenger jet planes that are built after the formation of new Russia and also that is the first passenger plane of SU company which previously built only well known SU military jets. The 33rd airplane is being assembled currently in Komsomolsk-on-Amur. So today we can see how SSJ100 is built on the Far East of Russia.

It must be noted that assimilation of new equipment is always related to certain difficulties. Problems of the past need to be eliminated and the airplanes must be modernized. The main thing about Sukhoi is that its pilots and constructors love the vehicle. They are engaged in airplane construction and are very proud of it.

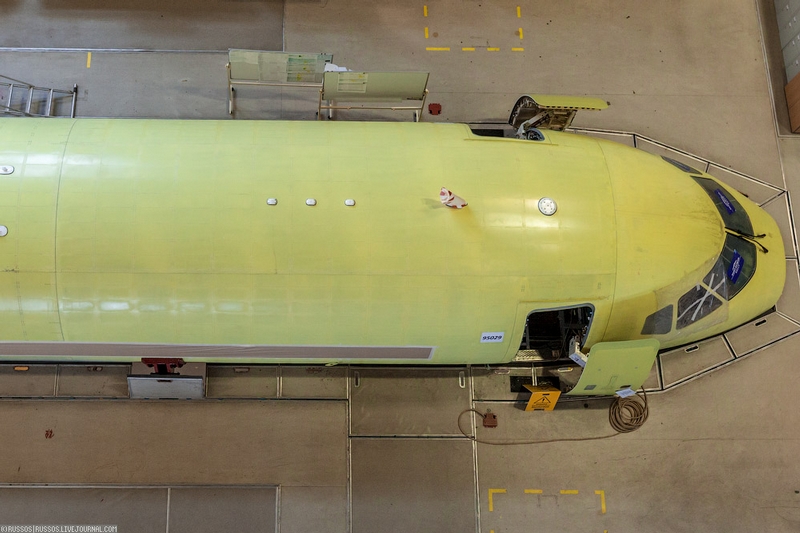

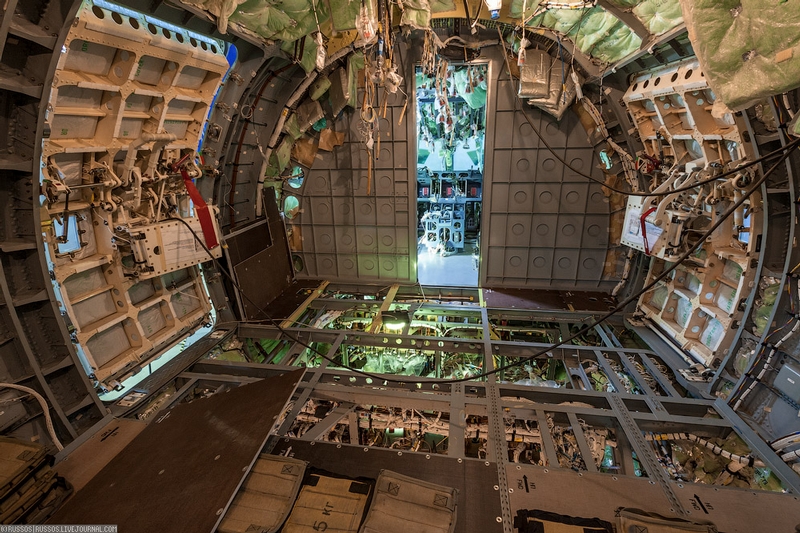

Assembly of a finished product occurs in nine sections. Here you can see the second, third, fourth, fifth and sixth sections of the final assembly workshop. The first one is not seen as it is hidden behind the central airplane. Still the entire wonder starts at the first section. The fuselage will soon be enriched with doors and a fin.

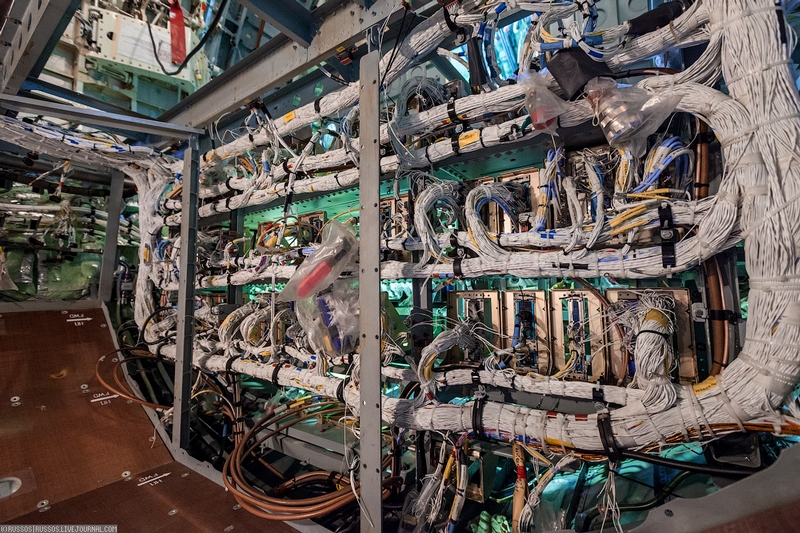

However, assembly of an airplane is still the simplest thing. As later it is followed by a very complicated and critical activity related to wiring harness layout and repair of power supply system.

Employees work daily in three shifts and every shift about 300 workers are engaged in the working process.

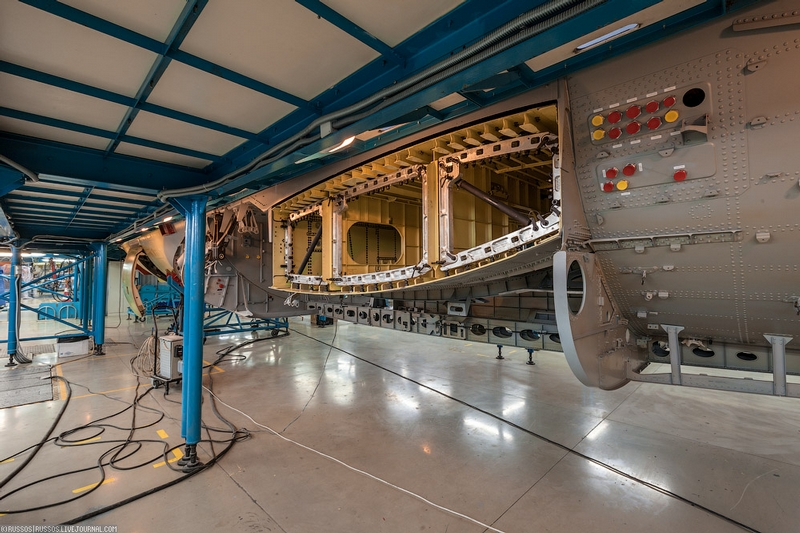

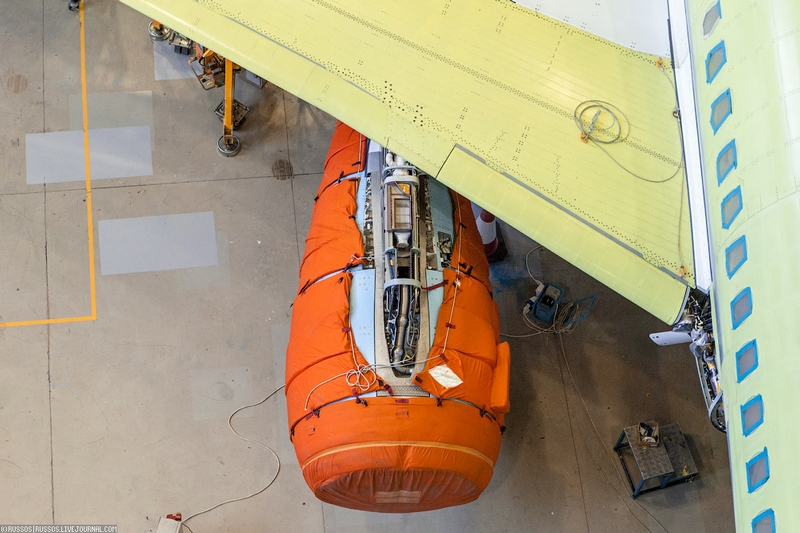

Center section of an airplane. Outer wings will be attached to it at the second section. One fuel reservoir is located in the very center of it, two others – in the outer wings.

Total fuel reserves account for 12690 kg.

By the way, it took 25 years to manufacture 74 Tu-204s and 24 Il-96s. And 25 both experimental and production airplanes have been produced starting from 2008.

The forebody and afterbody sections are made in Novosibirsk. They reach Komsomolsk-on-Amur following a standard road.

Electric wiring and engines have always been taken as the main problem of domestic aviation industry. And it seems that today the problem has been solved. Superjet is actually a flying computer and has many more wires than regular airplanes. The entire length of the electric network amounts to dozens km. It takes much time and efforts first to assembly it and then to control the quality. The routine and monotonous work is mainly fulfilled by women.

Today the cable network is being modernized.

Seam sealing the of the vertical fin produced in Novosibirsk though without some elements of the systems. That is why sealing is required at some sites of the fin.

Fuselage assembly with wings occurs at the 2nd site.

This very machine is assembled for a Mexican company. In this case assembly of electric wires was carried out in fuselage assembly.

Here the wing is connected with the center section. Holes are drilled and removed at the same place after all the parts are installed. Drilling and final bunching is done at the final assembly warehouse.

Wing flap assembly.

Works related to the electric system are completed at the third section.

The first commercial airplanes are returned from conservation and remade to demonstrate the interior of the business version of Sukhoi Business Jet.

Initially the airplane had to stay at the section for 30 days.

By 2015 the period will be decreased to 10 days which will help to produce around 30 airplanes that year.

Next year the period will be reduced even more leading to the production of 60 airplanes. It is rather complicated but possible.

Reduction of the period is explained by the usage of new technologies, motivation of personnel, change in the working technology and its optimization.

The engine pylon is a very light, small box with a minimum amount of details.

The airplane is certified as Protected Aircraft. A320, A330, A340, A380 and Sassault Falcon 7X have similar certificates. It means that the supervision system of Superjet controls the pilots and prevents them using unacceptable flying regimen.

The wind generator provides the machine with electric energy and pressure in case of the engine failure.

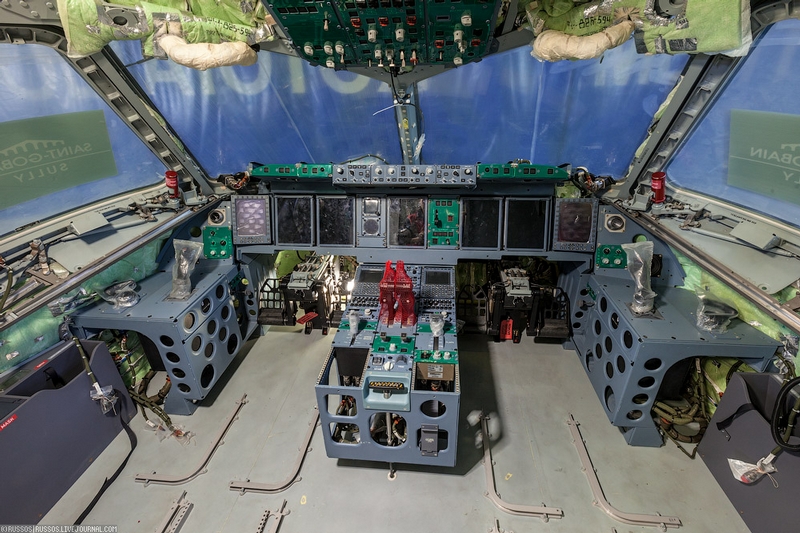

This is how the cabin looks. Later the airplane will be shifted to Ulyanovsk, Venice or Czechia where the interior is installed and the airplane is colored into corporate colors of the aviation company.

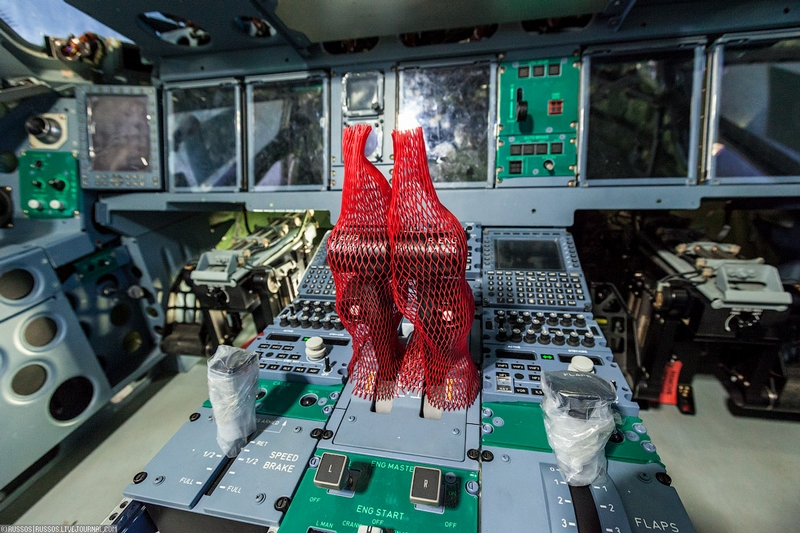

Pilot’s cabin.

Avionics is produced by the French company Thales. The same is for Airbus.

Protection from unauthorized use of a direct vision window for a period of final assembly. The employees decided that it will be safer with a lock.

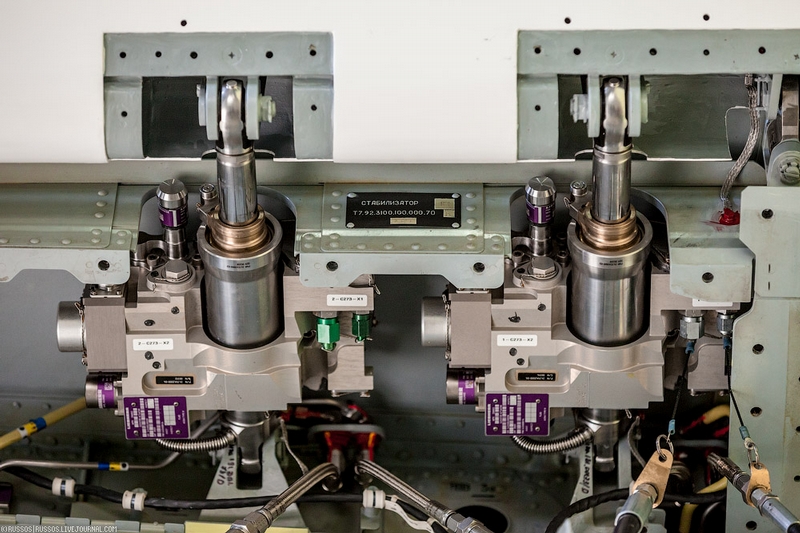

The airplane is unique because it has a digital fly-by-wire system. Abroad only A380 has a similar control system.

The sixth section.

Part of the air conditioning system.

The neutral gas system.

It is used to prevent the formation of inflammable fuel vapors in reservoirs by decreasing the amount of oxygen in them and nitrogen pressurization.

Engines are assembled at the sixth section. The airplane is weighted after fueling and defueling when the amount of trapped unusable fuel is calculated.

The engine demonstrated an amazing reliability. In April 2012 it was able to withstand bird strikes. It continued an uninterrupted operation after geese and swallows flew into the engine.

The sixth section has completed its work. Now all the systems of the plane will go through the stage of acceptance and control.

Soon it will fly for the first time.

SSJ 100LR out-of-range aircraft. Its experimental model made its first flight in February 2013.

In the Russian domestic market, the Sukhoi Superjet is intended to replace the aging Tupolev Tu-134 and Yakovlev Yak-42 aircraft.

Location: Komsomolsk-on-Amur

via russos

A great plane, and beautifully made, but some corrections to a few statements:

‘In April 2012 it was able to withstand bird strikes.’ — All engines can withstand bird strikes

‘The airplane is unique because it has a digital fly-by-wire system. Abroad only A380 has a similar control system.’ — All modern Airbus aircraft, and other, are fly-by-wire.

But, nice blog post and a beautiful airplane:)

@ B.Jerk:

You are wrong, it´s says DIGITAL fly-by-wire…

He is actually not wrong. Airbus launched full DIGITAL fly-by-wire in 1984. Today pretty much every modern Airliner is digital fly-by-wire^^

But also. Nice pictures. Hope these won`t crash like the last one….

I believe that crash was due to Pilot Error, not airframe failure. –Still though it’s not good when a plane on a high profile publicity tour crashes and kills people who are interested in buying.

Good luck to the Sukhoi. It has a tremendous amount of competition.

the painter girl is very pretty

Everything is amazingly made and is Russian style: how can work on airplane with metal tip high heel shoes??? (See the nice shaped girl lying on the floor, obviously taking reference point)

Clean working environment, modern technologies, pretty girls; where can I send my CV?

I think this is the model of airplane which crashed few months ago and killing all aboard during a demostration world tour. http://en.wikipedia.org/wiki/Mount_Salak_Sukhoi_Superjet_100_crash

And englishrussia.com mentioned the tour but nothing related to the crash?! Something has to be improved still, after all.

>According to sources within the investigating committee, the aircraft was in full working order and the incident was ascribed to human error.

How they can improve the brain of dead pilot, which turned off terrain warning system?

Highly intresting photos !

some great pictures but please, dont take any notice of the captions. there are so many errors in there!

I have a son who is 25 years old and is Autistic. He fixates on helicopters ever since he first saw one likely when he was two or three. All he wants to do is watch videos of helicopters or look at pictures. I have seen hundreds of hours and tens of thousands of pictures. The Russians have always been a pioneer in helicopter design and planes. Anyone that puts down Russian technology has no idea of what they are talking about.

Hand-painted yummy!

Thales is not French, it’s a Dutch company.

A friend of mine used to work there.

Sorry, Thales is French company! Previously named Thomson CSF and headquarter based in France

A plane build by the most beautiful woman on earth, who will not fly with them.